PCB Base Materials: Types and Properties

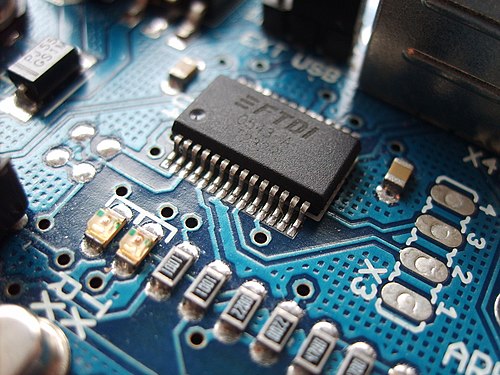

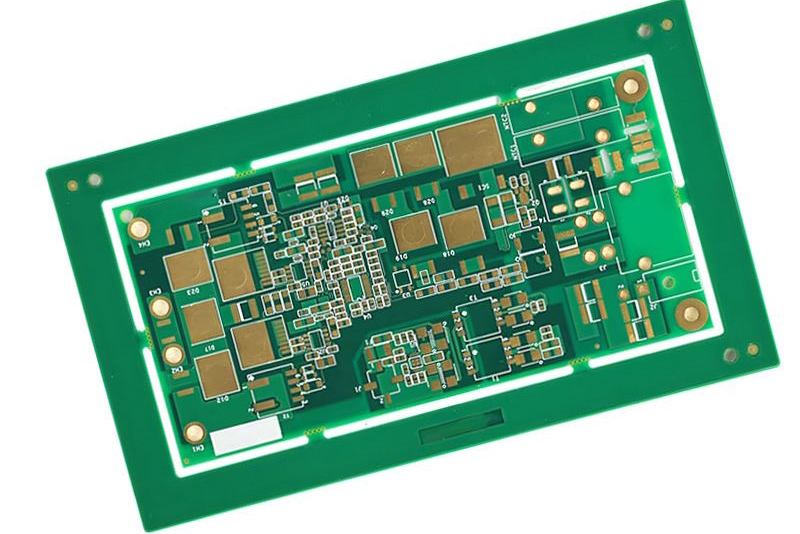

From laptops and smartphones to automotive electronics and medical devices, Printed Circuit Boards (PCBs) are everywhere in our lives. At the heart of each PCB lies its base material. An understanding of the types and properties of PCB base materials is required to select the right substrate for a specific application.

What Are PCB Base Materials?

A PCB base material—a typical substrate—serves two purposes: providing structural support for the circuitry and electrically insulating conductive copper traces. The base typically has a dielectric layer sandwiched between layers of copper. The substrate affects signal integrity, thermal stability, flexibility, cost, and even environmental resistance.

Further reading: The Evolution of Printed Circuit Boards (PCBs)

Common Types of PCB Base Materials

1. FR-4 (Flame Retardant 4)

FR-4 is by far the most widely used base material for printed circuit boards. It is a glass-reinforced epoxy laminate, made by impregnating woven fiberglass cloth with an epoxy resin binder.

FR-4 has excellent electrical insulation and heat resistance, with a Tg of 130°C to 180°C. Its dielectric constant is approximately 4.3–4.7 and it has low water absorption, making it a good, mid-range option for general PCB use.

FR-4 is used in consumer electronics, industrial controls, automotive electronics, and medium-speed digital applications.

2. CEM-1 and CEM-3 (Composite Epoxy Materials)

CEM-1 and CEM-3 are less expensive versions of FR-4, made with epoxy resin and paper or glass-fiber substrates. CEM-1 has a paper core with one layer of woven glass fabric reinforcement and is widely utilized for single-sided PCBs. In CEM-3, there is a glass-mat core, which offers improved dimensional stability and a white appearance.

They are mechanically weaker than FR-4 and are therefore more appropriate for consumer or low-end applications. They are also cheaper and easier to drill or punch. Common applications include household appliances, toys, and low-frequency analog circuits.

3. Polyimide

Polyimide-based materials are extremely flexible and possess excellent thermal stability and are therefore a material of choice for flexible and rigid-flex printed circuit boards.

They typically have a glass transition temperature (Tg) of above 250°C and a dielectric constant (Dk) of 3.2-3.5. They also offer excellent flexibility with good mechanical and chemical durability. Polyimide is typically used in aggressive applications such as aerospace systems, military electronics, medical devices, and wearable technology because of these characteristics.

4. High-Frequency (RF/Microwave) Laminates

In radio-frequency and high-speed digital applications, low dielectric loss and a well-controlled dielectric constant are desirable. Polytetrafluoroethylene (PTFE) composites, such as those produced by companies like Rogers and Taconic, are usually applied in these applications. These composites have a very low dielectric loss factor of approximately 0.0009 to 0.005. They also offer a stable dielectric constant of approximately 2.2 to 3.5.

These properties make PTFE composites offer excellent signal integrity at gigahertz frequencies. They are quite expensive, though, and are processed through complex methods. Radar systems, 5G base stations, satellite communication, and RF amplifiers are common applications of PTFE composites.

5. Metal-Core PCBs (MCPCB)

Instead of conventional epoxy resin or fiberglass, Metal Core Printed Circuit Boards (MCPCBs) utilize a metal base—often aluminum or copper—to achieve higher thermal conductivity. MCPCBs possess high thermal conductivity, typically ranging from 1 to 9 W/m·K, which allows for effective heat dissipation. A layer of insulation is placed between the metal core and the copper circuit in order to ensure electrical safety.

MCPCBs find common applications in LED lighting, power supplies, and automotive electronics, where heat management is critical.

6. Ceramic Substrates

High-end applications typically demand ceramic base materials such as aluminum nitride (AlN), alumina (Al₂O₃), or beryllium oxide (BeO) as substrates. These materials provide very good thermal conductivity with high electrical insulation. For example, aluminum nitride possesses high thermal conductivity of approximately 170 to 200 W/m·K. Ceramic substrates also offer high dielectric strength, making them suitable for high-stress applications.

Yet these materials are brittle and costly. They have uses in high-power electronics, laser drivers, and high-reliability aerospace products.

Choosing the Correct PCB Base Material

|

Base Material |

Thermal Resistance (Tg) |

Dielectric Constant (Dk) |

Thermal Conductivity |

Key Properties |

Typical Applications |

|

FR-4 |

130–180°C |

4.3–4.7 |

~0.3 W/m·K |

Good mechanical strength, flame retardant, low moisture absorption |

Consumer electronics, automotive, industrial controls |

|

CEM-1 / CEM-3 |

~110–130°C |

4.4–5.0 |

~0.25 W/m·K |

Cost-effective, lower strength, suitable for low-end applications |

Toys, household devices, low-frequency analog circuits |

|

Polyimide |

>250°C |

3.2–3.5 |

~0.2–0.4 W/m·K |

High flexibility, chemical resistance, excellent high-temp stability |

Aerospace, medical devices, flex/rigid-flex PCBs |

|

PTFE/RF Laminates |

~200–260°C |

2.2–3.5 |

~0.25–0.6 W/m·K |

Very low dielectric loss, excellent signal integrity at high frequencies |

5G, RF, microwave, satellite, radar |

|

Metal-Core (MCPCB) |

~130–180°C (insulating layer) |

4.0–7.0 (varies) |

1–9 W/m·K |

Superior heat dissipation, moderate cost, good mechanical durability |

LED lighting, power electronics, automotive |

|

Ceramics (AlN, Al₂O₃) |

>250°C |

6–9 (Al₂O₃), 8.5 (AlN) |

20–200 W/m·K |

Excellent thermal and dielectric performance, brittle, expensive |

Laser drivers, EVs, aerospace, high-power systems |

Conclusion

As a conclusion, PCB base material selection plays a critical role in determining the performance, reliability, and affordability of electronic products. For more information, please check Stanford Electronics.