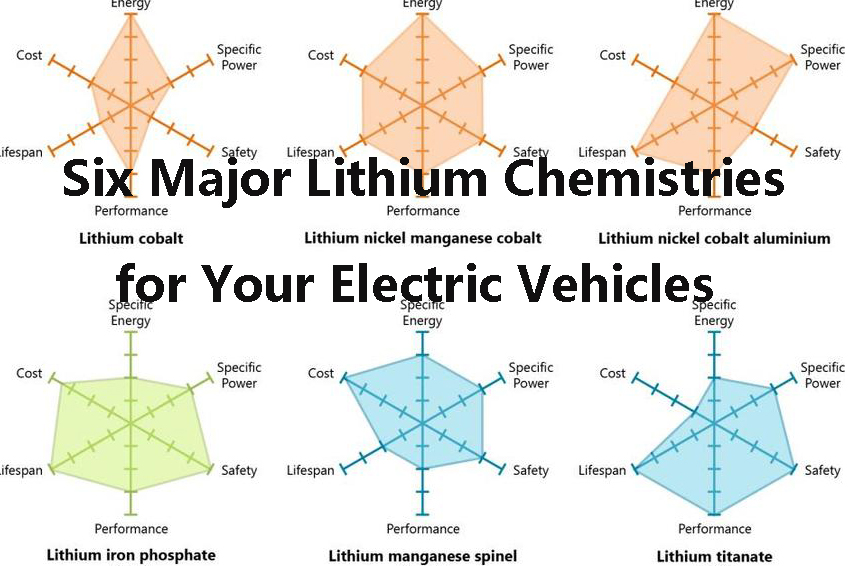

Six Essential Lithium Chemistries for Your Electric Vehicles

As the world speeds up its pursuit of electrification of vehicles, lithium batteries have become the cornerstone of this revolution. There is no one-size-fits-all battery. Different applications—whether for a forklift, electric vehicle, farm vehicle, or drone—each demand bespoke performance characteristics. Let us learn about the six most common lithium-based chemistries that are presently shaping the EV landscape:

[1]

[1]

1. LCO (Lithium Cobalt Oxide - LiCoO₂)

Applications: Smartphones, laptops, digital cameras

Key Characteristics: High energy density, poor thermal stability, short life cycle

LCO batteries are among the oldest lithium chemistries. Their high energy density and compact size make them ideal for small-scale electronics. However, their safety limitations and relatively short lifespan (500–1,000 cycles) make them unsuitable for large-scale or high-power applications. A high cobalt content also makes them unethical and environmentally concerning.

2. LMO (Lithium Manganese Oxide - LiMn₂O₄)

Applications: Power tools, e-bikes, medical devices

Key Characteristics: Good thermal stability, moderate energy density, high discharge rates

LMO chemistry offers a safer alternative to LCO with improved thermal stability and higher current delivery. Reduced capacity is compensated for by the ability to deliver high power bursts. Like LCO, though, LMO is typically limited to small or medium-sized applications due to moderate cycle life (300–700 cycles).

Further reading: Lithium-Ion Batteries: Function, Materials, and Applications

3. LFP (Lithium Iron Phosphate - LiFePO₄)

Applications: Industrial equipment, logistics vehicles, agriculture, maritime transportation

Key Characteristics: Outstanding safety, long cycle life, flat discharge curve, cobalt-free

LFP is gaining popularity in industrial and now also in automotive uses. It has excellent thermal stability and life—over 4,000 cycles, and potentially as high as 6,000 with advanced Battery Management Systems (BMS). While historically the energy density has been a limiting aspect, newer LFP batteries now have up to 170 Wh/kg, with future projections as high as 230 Wh/kg.

Its flat voltage discharge curve ensures stable performance throughout the battery's life, though it also complicates state-of-charge estimation and demands intelligent BMS. Above all, LFP's cobalt-free chemistry makes it a sustainable and ethical option. OEMs like Tesla and BYD are now using LFP in standard-range vehicles due to its cost and safety track record.

4. NMC (Nickel Manganese Cobalt - LiNixMnyCozO₂)

Applications: Passenger EVs, plug-in hybrids

Key Characteristics: High energy density, good balance of cost, safety, and performance

NMC chemistry is the dominant chemistry in the automotive sector due to its high gravimetric energy density (220–240 Wh/kg) and volumetric energy density (up to 500 Wh/L). It has a balance of power and weight, which is highly essential in providing extended driving ranges. NMC 111, 622, and 811 are a few of its variants, which differ in nickel, manganese, and cobalt content, with recent efforts at reducing cobalt usage to reduce costs and ethical concerns.

Despite modest cycle life (~2,000 cycles), NMC batteries are a good fit for vehicles that see relatively few numbers of charge cycles during their lifetimes.

5. NCA (Nickel Cobalt Aluminum - LiNiCoAlO₂)

Applications: High-performance EVs

Key Characteristics: Highest energy density, moderate cycle life, lower thermal stability

NCA shares the same characteristics as high-performance NMC cells but offers even higher energy densities (up to 300 Wh/kg). It does, however, require careful thermal management due to decreased inherent safety. It's most utilized in high-performance electric vehicles where energy capacity per weight is of the highest priority. Tesla uses NCA extensively in its performance models.

6. LTO (Lithium Titanate - Li₄Ti₅O₁₂)

Applications: AGVs, forklifts, heavy-duty industrial vehicles

Key Characteristics: Very long life cycles (15,000–20,000), fast charging, very low energy density

LTO is the marathon runner of lithium chemistries. Its very long life makes it a good fit for fleet vehicles and industrial equipment that are in heavy use and recharged on a regular basis. LTO's energy density (70 Wh/kg) and nominal voltage (2.4 V) are its biggest drawbacks, which result in heavier and larger battery packs.

Its cost and limited supply chain also discourage widespread adoption, though it is attractive for mission-critical applications requiring ultimate reliability.

Matching Chemistry to Application

The success of an electrification project depends on matching the battery chemistry to the specific needs of the application:

• Automotive Industry (NMC & NCA): Cars are helped by high energy density and fast charging. Since they don't cycle much, compromised battery life is acceptable.

• Industrial Segment (LFP & LTO): Safety, longevity, and cycle life take top priority. Applications like AGVs and airport vehicles prefer reliable performance over compactness.

• Portable Tools (LCO & LMO): These chemistries are small and light and are ideally suited for handheld applications but not for large or demanding applications.

• Stationary Energy Storage (LFP): In grid applications or renewable energy storage, where less emphasis is on space, LFP offers a low-cost and long-duration option.

Summary Table

|

Parameter |

LCO |

LMO |

LFP |

NMC |

NCA |

LTO |

|

Full Name |

Lithium Cobalt Oxide |

Lithium Manganese Oxide |

Lithium Iron Phosphate |

Nickel Manganese Cobalt |

Nickel Cobalt Aluminum |

Lithium Titanate |

|

Nominal Voltage (V) |

3.6 |

3.7 |

3.2 |

3.6 |

3.6 |

2.4 |

|

Gravimetric Energy Density (Wh/kg) |

200 |

150 |

177 (up to 230) |

220–240 |

250–300 |

60–70 |

|

Volumetric Energy Density (Wh/L) |

400 |

350 |

384 |

500 |

550 |

177 |

|

Cycle Life |

500–1,000 |

300–700 |

>4,000 (up to 6,000) |

~2,000 |

~1,000 |

15,000–20,000 |

|

Discharge Rate (C) |

1C |

1C–10C |

1C–3C |

2C–3C |

2C–3C |

4C–8C |

|

Key Strengths |

High energy density, compact |

Thermal stability, high output |

Safety, long life, no cobalt |

Energy density, balanced traits |

Very high energy density |

Long life, fast charge, safe |

|

Main Limitations |

Safety risks, costly cobalt |

Lower capacity |

Lower energy density, flat voltage |

Contains cobalt, moderate life |

Lower safety, shorter life |

Low energy density, bulky |

|

Typical Applications |

Consumer electronics |

Power tools, e-bikes |

Industrial, logistics, agriculture |

Electric vehicles, hybrids |

High-performance EVs |

24/7 industrial, AGVs, forklifts |

For more information, please check Stanford Electronics.

Conclusion

Each lithium chemistry also has its strengths and trade-offs. Rather than competing, they coexist peacefully to serve different segments of the electrification market. The right choice is a function of the specific operational requirements of your car or equipment—energy needs, life expectancy, safety, cost, and form factor.

Reference:

[1] Lemon, Scott & Miller, Allan. (2013). Electric Vehicles in New Zealand: Technologically Challenged?.