Lithium Niobate As Compared to Other Functional Materials

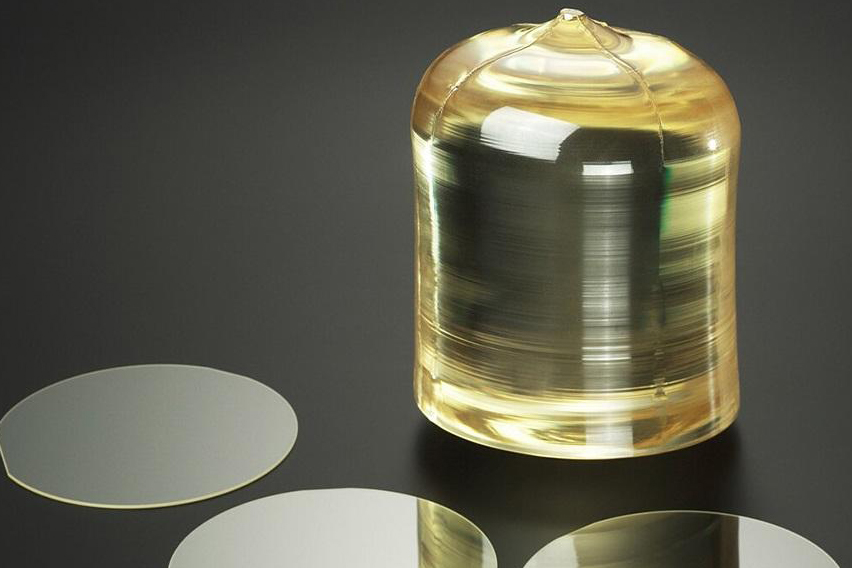

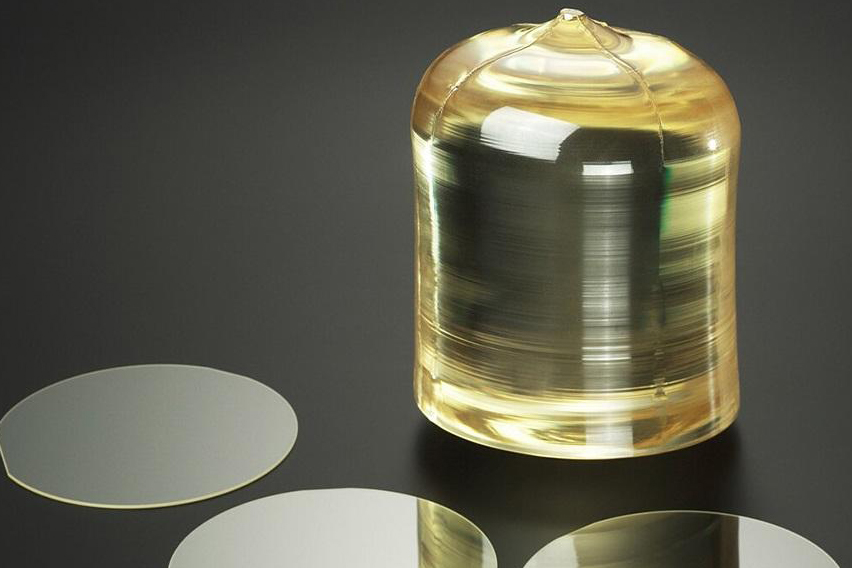

Lithium niobate (LiNbO₃) has emerged as a cornerstone material in optoelectronics and photonics in recent materials science. Its multidisciplinary merits of high electro-optic, acousto-optic, and nonlinear optical performances make it an essential material for use ranging from high-speed telecommunications to laser frequency conversion and optical signal processing.

Lithium Niobate vs Lithium Tantalate

Lithium tantalate is the chemical and structural equivalent of lithium niobate. They are both ferroelectric crystals with strong electro-optic properties, but there are certain distinctions that influence their use.

- Electro-Optic Performance: Lithium niobate possesses higher electro-optic coefficients, thereby having higher efficiency in optical switches, modulators, and frequency converters. This is one of the key factors why LiNbO₃ dominates telecommunications and high-speed photonics devices.

- Thermal Stability: Lithium tantalate is a bit more thermally stable, with greater performance ideally suited for pyroelectric detectors, infrared sensors, and temperature-detecting purposes. Products that must respond reliably over wide temperature ranges utilize LiTaO₃'s ability.

- Availability and Cost: Lithium niobate is easy to come by in large, high-quality crystals at competitive price. Such availability facilitates inexpensive mass production of photonic devices.

In summary, lithium niobate excels at high-performance optical communications, while lithium tantalate is appropriate for sensors and infrared detection devices.

Lithium Niobate vs. Quartz

Quartz is a natural crystal that has been an industry standard in electronics for decades. It is prized for its mechanical stability, chemical stability, and piezoelectricity, which render it particularly well-suited for use in oscillators, resonators, and timing circuits. However, lithium niobate has several attributes in excess of quartz.

- Piezoelectricity: While quartz produces reliable piezoelectric response, lithium niobate has much larger piezoelectric coefficients, making it possible to produce very sensitive surface acoustic wave (SAW) filters for wireless and mobile communications.

- Nonlinear Optical Properties: Quartz does not exhibit any nonlinear optical properties, limiting its suitability for laser frequency conversion or parametric oscillation. Lithium niobate, on the other hand, is highly suitable for frequency doubling and other nonlinear optical phenomena and plays a key role in modern laser systems.

- Mechanical Considerations: Quartz is even more durable and resistant to fracture than lithium niobate, which is capable of being brittle under mechanical stress. Thus, quartz is better suited in hostile or vibration-heavy environments where optical precision matters less.

Overall, quartz remains the material of choice for timing, control, and rugged electronic devices, while lithium niobate fosters innovation in optical modulation, signal processing, and nonlinear optics.

Lithium Niobate vs. Thin-Film Materials

The recent developments in integrated photonics introduced thin-film materials such as silicon (Si), silicon nitride (Si₃N₄), and aluminum nitride (AlN) to the platform. While these have their own strengths in certain niches, particularly in large-scale integration and chip-based technology, lithium niobate still has certain special strengths.

- Silicon Photonics: Silicon can be combined with CMOS processing, allowing highly scalable photonics circuits. Its poor electro-optic effect, however, limits high-speed modulation capability.

- Thin-film lithium niobate (TFLN) to the rescue: compact integration and improved modulation efficiency.

- Aluminum Nitride: AlN has strong piezoelectricity and mechanical stability built-in, but lithium niobate cannot be matched by AlN in nonlinear optical efficiency. For applications demanding high-accuracy frequency conversion or optical switching, LiNbO₃ remains the better choice.

- Thin-Film Lithium Niobate (TFLN): This technology combines lithium niobate's inherent advantages with on-chip scaling, enabling compact, high-performance modulators, optical switches, and integrated photonic circuits. TFLN is rapidly becoming a platform of choice for future optical communication systems.

Thus, while silicon and other thin films dominate mass-production scalability, lithium niobate remains the performance champion in precision photonics, particularly for high-speed, low-loss optical modulation.

Comparison Table

|

Material |

Strengths |

Limitations |

Applications |

|

LiTaO₃ |

Thermal stability, good electro-optic |

Lower efficiency than LiNbO₃ |

IR sensors, pyroelectric detectors |

|

Quartz |

Durable, stable, reliable piezoelectric |

No nonlinear optics, weaker piezoelectric |

Oscillators, resonators, timing |

|

Si |

CMOS-compatible, scalable |

Weak electro-optic effect |

Integrated photonic chips |

|

AlN |

Strong piezoelectric, robust |

Poor nonlinear optics |

RF devices, MEMS |

|

TFLN |

High electro-optic, chip-scale |

Complex fabrication |

High-speed modulators, photonic circuits |

For more optic devices and wafers, please check Stanford Electronics.

Conclusion

Through its bridging of performance, integration capability, and optical precision, lithium niobate is a material of continued significance in modern-day photonics, ensuring it will continue to shape the future of high-speed optical technology.