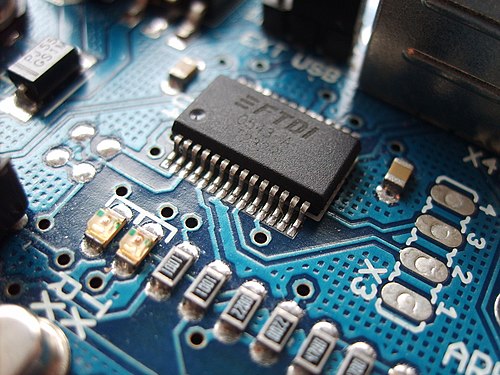

Alumina Substrates in PCB Materials: Properties and Applications

Printed circuit boards (PCBs) are the foundation of contemporary electronics. Alumina substrates have long been one of the most reliable and adaptable options. Their unique combination of electrical insulation, thermal conductivity, and mechanical strength has established them as a standard for high-performance electronic systems.

What Are Alumina Substrates?

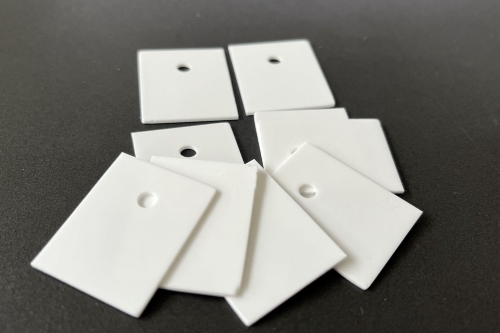

Alumina, or aluminum oxide (Al₂O₃), is a ceramic with a long history of use in the electronics industry. For the manufacture of PCBs, it is processed into thin, flat substrates for use as the insulating base for conductive circuit layers. The substrates are produced by ceramic powder processing techniques such as tape casting, followed by high-temperature sintering to create dense, stable plates.

Different grades of alumina are manufactured to fulfill specific demands. The common industrial grade is 96% alumina, which offers a reasonable balance of electrical, thermal, and mechanical performance. For more demanding applications, high-purity grades such as 99.5% alumina are used, with better dielectric strength, insulation, and thermal stability.

Properties That Make Alumina Unique

The attraction of alumina substrates is the balance of properties that they unite. Being an electrical insulator, alumina offers superb isolation of conductive traces, even at high voltage, with dielectric strengths in excess of 10 kV/mm. Such reliability is perfect for circuits where insulation cannot be afforded to be compromised.

Thermal conductivity is also a key consideration. While not the match of newer ceramics like aluminum nitride, alumina's 20–30 W/m·K conductivity is sufficient for heat dissipation in many high-power and high-frequency applications. Alumina substrates help promote longer device life and stable performance by keeping components cool.

Mechanical strength also enhances its popularity. Alumina is tough, wear-resistant, and dimensionally stable over a broad range of temperatures, which means that it can withstand the rigors of production, assembly, and tough operating conditions without deforming or deteriorating. To this is added its chemical stability—resistance to oxidation, corrosion, and a broad range of chemicals—enabling it to function effectively in corrosive environments.

Most importantly, perhaps, alumina offers an attractive cost-performance balance. Other materials, such as silicon nitride or aluminum nitride, might excel in some of the properties of alumina, but at a much higher price. Alumina, however, is dependable at a cost where it can be widely utilized.

Related reading: PCB Substrates in High-Frequency Electronics

Manufacturing and Processing

Alumina substrates are provided in various sizes and thicknesses, normally between 0.25 mm and 1.0 mm. Once formed, they can be precisely shaped, diced, or drilled, then metallized to carry pathways. There are various metallization techniques possible, based on the demands of the circuit.

Thick film technology is the screen-printing of conductive pastes of silver, gold, or copper metals on the surface and then firing them to create robust conductive tracks. Thin film technology is the utilization of vacuum deposition methods such as sputtering to obtain highly precise metal patterns and is therefore appropriate for circuits with very thin lines. For applications that require high current-carrying capacity and superior thermal management, direct bonded copper (DBC) processing bonds a copper layer directly to the ceramic substrate.

These processes give engineers flexibility in creating everything from simple circuit boards to complex multilayer assemblies, allowing alumina substrates to be used in a wide range of applications.

Applications across Industries

Thanks to their well-balanced properties, alumina substrates have managed to find their way into virtually every field of advanced electronics. In power electronics, they are being widely used in such products as rectifiers, power transistors, and converters, where they insulate while efficiently dissipating heat. In the rapidly evolving field of LED lighting, alumina substrates ensure thermal stability and long lifetimes for high-brightness LEDs.

The automotive industry relies on alumina substrates in heat- and vibration-exposed systems, such as engine control modules and advanced driver-assistance systems. Low dielectric loss also renders them a material of choice in RF and microwave circuits, facilitating telecommunications infrastructure and radar technology.

Medical equipment is another principal area of use. The biocompatibility, insulation, and thermal properties of alumina make it suitable for diagnostic equipment and implantable sensors. Finally, in aerospace, alumina substrates supply the strength, chemical resistance, and dimensional stability that is required in avionics and satellites.

Conclusion

Alumina substrates have emerged as a cornerstone material in PCB technology. Through the provision of good electrical insulation, dependable thermal management, mechanical robustness, and low cost, they realize an optimal balance that meets the needs of industries from automotive to telecommunications, medical, and aerospace.

While emerging ceramic materials may outclass alumina in certain individual traits, the equilibrium of performance and cost ensures that alumina substrates will remain a key material in the production of dependable high-performance electronic systems.