PCB Substrates in High-Frequency Electronics

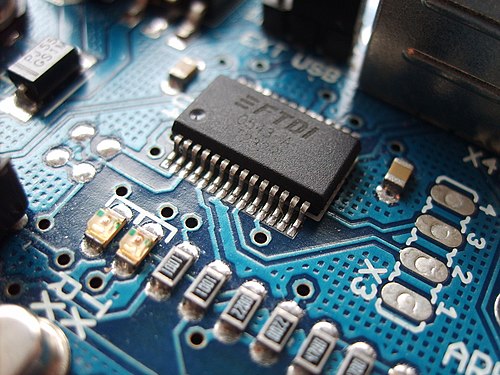

The rapid advancement of wireless communication, radar systems, satellite technology, and high-speed data processing has dramatically increased the demand for printed circuit boards (PCBs) optimized for high-frequency electronics. At the heart of these specialized PCBs lies the choice of substrate material. They directly impacts signal integrity, thermal management, reliability, and overall device performance.

The Importance of Substrate Materials in High-Frequency PCBs

High-frequency PCBs operate at radio frequencies (RF), microwave, and millimeter-wave bands—typically ranging from hundreds of megahertz (MHz) to tens or hundreds of gigahertz (GHz). At these frequencies, electrical signals behave differently than at lower frequencies, and subtle material characteristics become critical.

The substrate in a PCB serves as the electrical insulator and mechanical support for copper traces. Its dielectric properties, including dielectric constant (Dk) and loss tangent (Df), dictate how signals propagate, how much energy is lost, and how susceptible the system is to noise and interference.

Further reading: The Evolution of Printed Circuit Boards (PCBs)

Key Substrate Material Properties for High-Frequency Use:

- Dielectric Constant (Dk): Determines signal propagation speed and impedance. Stable and low Dk values are preferred to maintain predictable transmission characteristics.

- Dissipation Factor (Df or dielectric loss): Indicates energy lost as heat during signal transmission. Lower Df means less signal attenuation, vital at high frequencies.

- Thermal Conductivity: High-frequency circuits often generate substantial heat; substrates with better thermal management help maintain performance and longevity.

- Moisture Absorption: Water drastically increases dielectric loss and shifts dielectric constant, degrading signal integrity.

- Coefficient of Thermal Expansion (CTE): Materials with compatible CTEs reduce mechanical stress and failure during thermal cycling.

Common Substrate Materials for High-Frequency PCBs

1. PTFE-Based Laminates (Teflon)

PTFE (Polytetrafluoroethylene) is the gold standard for high-frequency PCB substrates, widely used in RF and microwave applications due to its excellent electrical properties.

- Dielectric Constant: Typically 2.1 to 2.5, very low and stable across frequency ranges

- Dissipation Factor: Extremely low (as low as 0.0009), minimizing signal loss

- Thermal Resistance: High Tg (~260°C)

- Moisture Absorption: Very low

Advantages:

- Outstanding signal integrity with minimal insertion loss

- Very stable dielectric properties across temperature and frequency

- Compatible with flexible and rigid PCBs

Challenges:

- Difficult and costly to process (requires specialized drilling and plating)

- Lower mechanical strength compared to epoxy-based laminates

Applications:

5G infrastructure, radar systems, satellite communications, aerospace and defense electronics, high-frequency filters, and antennas.

2. Ceramic-Filled PTFE and Hybrid Laminates

To overcome PTFE’s mechanical and fabrication challenges, manufacturers often reinforce PTFE with ceramic fillers like silica or alumina.

- Dielectric Constant: Tunable, typically 2.5–3.5 depending on filler content

- Dissipation Factor: Still very low (~0.001 to 0.005)

- Improved Mechanical Strength and Dimensional Stability

These hybrid materials offer a good balance between electrical performance and manufacturability, making them popular for complex, multilayer high-frequency boards.

3. High-Speed FR-4 and Modified Epoxy Laminates

Standard FR-4 epoxy substrates exhibit too much dielectric loss and variability in Dk for most high-frequency applications. However, modified FR-4 variants with reduced dielectric constants and loss tangents are available for frequencies up to several GHz.

- Dielectric Constant: 3.7–4.3

- Dissipation Factor: Typically around 0.015–0.02 (higher than PTFE)

- Thermal Resistance: 130–180°C

These materials are cost-effective and compatible with standard PCB manufacturing but are limited in applications requiring ultra-low loss or above 10 GHz frequencies.

4. Ceramic Substrates

Ceramic materials such as aluminum oxide (Al₂O₃) and aluminum nitride (AlN) are used for ultra-high frequency and high-power applications, offering exceptional thermal and electrical performance.

- Dielectric Constant: Al₂O₃ (~9.0), AlN (~8.5)

- Dissipation Factor: Very low

- Thermal Conductivity: Extremely high (AlN up to 200 W/m·K)

Ceramic substrates combine excellent heat dissipation with good dielectric stability, critical for high-power RF amplifiers and microwave devices. The trade-off includes higher cost and brittleness.

|

Property |

PTFE-Based Laminates |

Ceramic-Filled PTFE / Hybrids |

High-Speed FR-4 / Modified Epoxy |

Ceramic Substrates (Al₂O₃, AlN) |

|

Dielectric Constant (Dk) |

2.1 – 2.5 |

2.5 – 3.5 (tunable) |

3.7 – 4.3 |

Al₂O₃: ~9.0AlN: ~8.5 |

|

Dissipation Factor (Df) |

Extremely low (as low as 0.0009) |

~0.001 – 0.005 |

~0.015 – 0.02 |

Very low |

|

Thermal Conductivity |

High (Tg ~260°C) |

Moderate to high |

Moderate (Tg 130–180°C) |

Very high (AlN up to 200 W/m·K) |

|

Moisture Absorption |

Very low |

Low |

Moderate to high |

Very low |

|

Key Advantages |

Excellent electrical performance, low loss, stable over temperature |

Good balance of performance and processability, improved mechanical strength |

Cost-effective, compatible with standard fabrication |

Exceptional heat dissipation and dielectric stability |

|

Typical Applications |

5G, radar, satellite, aerospace, antennas |

Multilayer RF boards, defense, telecom |

Mid-speed digital, RF up to several GHz |

High-power RF amplifiers, microwave, aerospace systems |

Conclusion

The substrate is a foundational element in high-frequency PCB design, directly influencing electrical performance, signal integrity, thermal management, and long-term reliability. For more information, please check Stanford Electronics.