Comparative Analysis of Solar Cell Materials: Silicon, Perovskite, and CIGS

Introduction

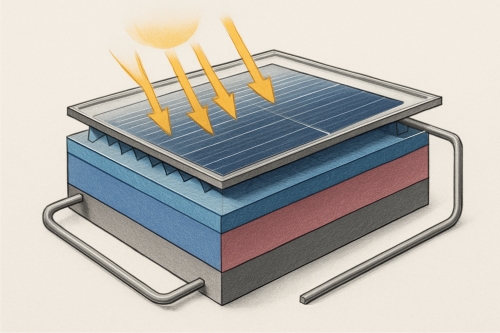

The most researched and commercially used solar cell materials include silicon, perovskite, and CIGS. Each of these materials is appropriate for applications that range from residential rooftop panels to flexible, lightweight solar devices. A comparison is made here between these three leading solar cell materials based on efficiency, stability, cost, and application suitability.

1. Silicon Solar Cells

Silicon continues to dominate the solar industry, with over 90% of the global PV installations. Silicon solar cells are usually available in two forms: monocrystalline and polycrystalline.

Monocrystalline silicon provides high efficiency, normally in the range of 20–26%, because the uniformity of crystal lattice allows electrons to flow with very little resistance. Polycrystalline silicon is cheaper but somewhat less efficient; efficiencies are generally between 15 and 20%.

Solar cells made of silicon demonstrate really high stability and can serve for more than 25 years. They also operate well under various conditions, such as high temperatures and changing sunlight intensity. Still, the preparation of high-purity silicon is energy-intensive in its manufacture, increasing the initial cost of silicon panels.

In a nutshell, silicon's performance and reliability in the long run prove to be perfect for fixed installations where maintenance costs and panel longevity play a vital role. The main limitation is in weight and rigidity, restricting the application of silicon in flexible or lightweight solar applications.

2. Perovskite Solar Cells

PSCs have lately emerged as a promising next-generation technology by combining high efficiency with the promise of low-cost manufacture. These perovskites are a class of materials with an ABX₃ crystal structure, usually incorporating lead or tin halides.

Perovskite cells have achieved PCEs of over 26% in lab-scale devices, rivaling the best silicon cells. They are lightweight and thin and can be fabricated by solution-processing methods, including roll-to-roll printing, which dramatically reduces manufacturing costs.

Despite these advantages, stability and degradation remain major challenges. The perovskite materials are sensitive to moisture, oxygen, UV light, and heat, reducing its operational lifespan to 1-5 years in unprotected environments. Research is underway to enhance stability through encapsulation techniques, compositional engineering, and tandem designs combining perovskite with silicon.

In summary, the high efficiency of perovskites is complemented by their versatility in form factors for innovative applications, ranging from flexible solar panels to transparent windows with integrated solar energy generation. And their stability solutions are maturing towards commercial viability.

Related reading: The Advantages and Disadvantages of Perovskite Solar Cells

3. CIGS Solar Cells

CIGS, or Copper Indium Gallium Selenide, is a thin-film photovoltaic technology that boasts flexibility, lightweight design, and a moderate efficiency rate. The cells are usually fabricated through depositing a thin semiconductor layer onto a substrate-such as glass, metal, or plastic.

CIGS solar cells usually reach efficiencies of 15–22%, higher than most other thin-film technologies but slightly lower than top-performing perovskite or monocrystalline silicon cells. One of the main advantages of CIGS is its excellent absorption coefficient, enabling thin layers (~1–2 μm) to absorb sufficient sunlight. This then leads to lightweight, flexible modules that may be applied to portable, curved, or otherwise unconventional surfaces.

CIGS panels are durable and resist moisture and heat much better than early perovskites, although generally less stable than silicon. The manufacturing process involves rare and expensive elements like indium and gallium, which can impact cost and scalability.

CIGS cells are particularly effective in applications for which flexibility, lightweight design, or integration into curved surfaces is required. However, scarcity restricts large-scale implementation of their raw materials.

Comparative Overview

|

Property |

Silicon |

Perovskite |

CIGS |

|

Efficiency |

15–26% |

15–26% (lab-scale) |

15–22% |

|

Stability/Lifetime |

25+ years |

1–5 years (improving) |

10–20 years |

|

Cost |

Moderate–High |

Low (potential for mass production) |

Moderate–High |

|

Flexibility |

Rigid |

High (thin-film possible) |

High (thin-film) |

|

Manufacturing |

Energy-intensive |

Low-energy, scalable |

Moderate complexity |

|

Applications |

Residential, commercial, utility |

BIPV, flexible panels, tandem cells |

Flexible panels, portable solar devices |

For more information, please visit Stanford Electronics.

How to Choose

Each solar cell material has different advantages and trade-offs:

- Silicon is the generic material of choice, appropriate for fixed large-format solar installations because it provides good long-term stability, reliability, and efficiency.

- Perovskite has the potential for low-cost manufacture with outstanding efficiency, making it a next-generation material for flexible applications and tandem devices. However, stability remains an issue.

- CIGS presents a balance between flexibility and moderate efficiency, suitable for portable or unconventional solar applications. However, its reliance on rare elements may limit large-scale deployment.