Top 5 Reasons Why Silicon is Indispensable in the Electronics Industry

Silicon has long been the backbone of electronics, from smartphones and computers to solar panels and complex medical devices. But interest in finding alternatives has been building over the years, yet silicon remains at the top due to its unrivaled combination of electrical properties, cost-effectiveness, and adaptability.

1. Semiconductor Properties of Silicon

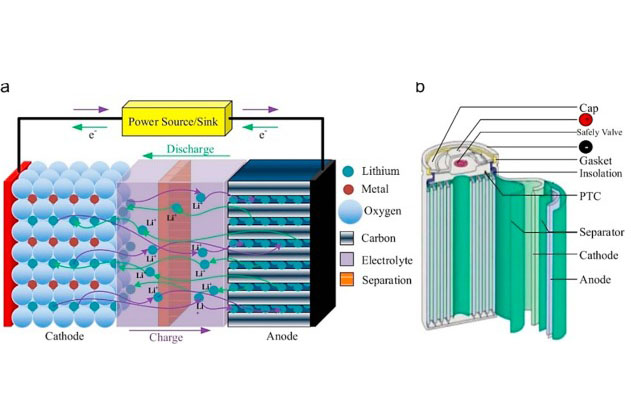

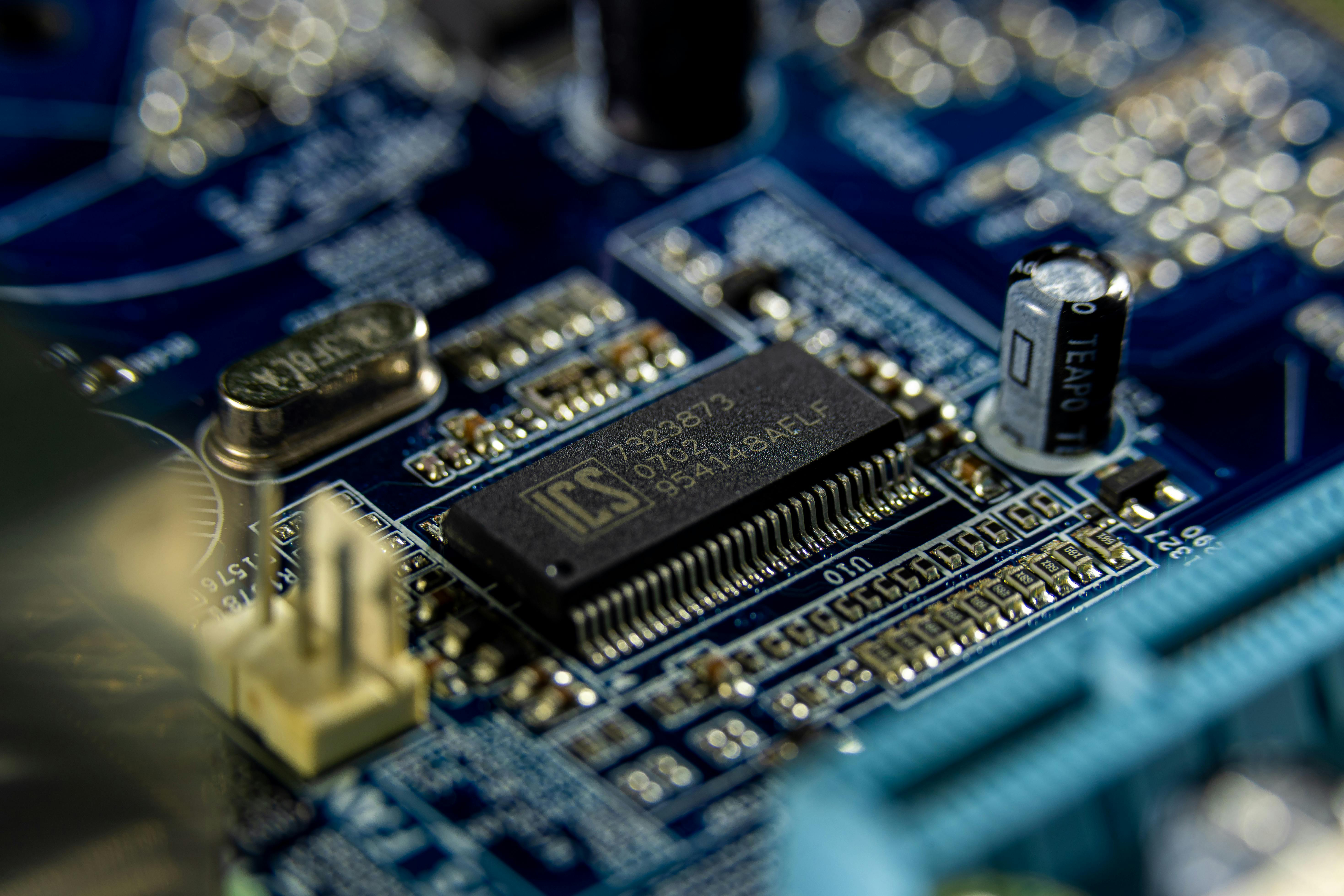

The main reason silicon is used so much in electronics is because it is a semiconductor. Unlike conductors, such as copper, or insulators like rubber, silicon can be manipulated to act as both a conductor and an insulator depending on the doping process. This makes it an ideal material for the building blocks of modern electronic devices: transistors, diodes, and integrated circuits.

• Semiconductor behavior: It allows silicon to conduct electricity under certain conditions and insulate at others; hence, it is the perfect material for controlling the flow of electrical current.

Because doping with such elements as phosphorus or boron permits very accurate control of its electrical properties, it allows for the construction of very efficient and tailored components targeted at specific applications.

Example Application: Transistors made of silicon in microprocessors run computers, smartphones, and laptops, and are the enablers of everything from basic calculations to AI-related tasks.

2. High Abundance and Cost-Effectiveness

Silicon is one of the most abundant elements available on Earth, making large-scale manufacturing with it considerably economic and sustainable. Most of the silicon comes from silica, which is found in sand, quartz, and rock. This abundance keeps the cost of the material quite low when compared with other semiconductors such as gallium arsenide (GaAs) and germanium (Ge), and hence it represents an ideal choice for mass production.

• Cost advantage: Being widely available and relatively easy to refine, silicon can be produced in bulk at a fraction of the cost compared to other raw materials, thereby enabling device manufacturers to produce affordable devices.

• Inexpensive processing: The silicon wafers are cut from large silicon crystals and then can be processed into microchips with minute details at low costs for mass production.

Example Application: The low cost of silicon-based photovoltaic panels has driven the wide use of renewable energy solutions across the globe.

3. Excellent thermal stability

Among other benefits, silicon has very good thermal stability; in fact, this is an issue of great importance for each electronic component to be able to operate properly within a wide range of temperatures. In conditions when materials commonly start degrading or losing their properties, silicon maintains its mechanical integrity and electric performance even for heat-sensitive environments.

Silicon can operate in the temperature range of -50°C to 150°C with no significant loss of performance, which is particularly important for devices supposed to operate at high temperatures, including automotive electronics, power supplies, and power transistors.

Its ability to dissipate heat means that this adhesive is also suited for applications that involve the cooling of high-density circuits.

Example Application: Automotive electronics, including engine control units and infotainment systems, rely on the thermal stability of silicon to operate in the heat generated within a vehicle's engine.

4. Versatility and Integration into Complex Systems

Silicon is distinctive for the versatility of its application within the electronics industry. It forms a part of everything, from simple components like diodes and transistors to highly complicated ones like microprocessors, memory chips, and sensors. With silicon's ever-growing ability to integrate into increasingly complicated systems, it has become indispensable for a wide range of industries, ranging from consumer electronics and automotive to telecommunications and healthcare.

Silicon integration in SoC designs provides smarter, powerful, and compact electronic devices.

Silicon can be used for a wide range of both analog and digital devices; it can thus be flexible in various uses across many markets.

Example Application: Smartphones contain several different silicon chips, which control everything from communication (Wi-Fi, Bluetooth) to processing power (CPU, GPU), display drivers and memory storage.

5. The Role of Silicon in Renewable Energy and Green Technology

Silicon has become one of the main elements in renewable energy technologies, mainly in solar energy systems. Most modern solar panel systems incorporate the technology of photovoltaic conversion of sunlight into electrical energy using silicon-based photovoltaic cells. It is for this reason that the role of silicon in green technologies for global carbon footprint minimization has become one of the most important.

Efficiency: Silicon-based solar cells are highly efficient, and research has been continually improving the efficiency ratings. The use of silicon in solar energy systems is instrumental for both scalable and cost-effective generation of solar power.

Long life: The robustness of silicon means that solar panels last decades, thus offering a low-maintenance, long-term source of energy.

Example Application: Extensively used silicon-based solar panels have led to intense efforts globally to increase the use of renewable energy and reduce dependency on fossil fuels.

Why Silicon Will Continue to Lead the Electronics Industry

The combination of semiconductor properties, cost-effectiveness, thermal stability, versatility, and its growing importance in renewable energy systems makes silicon indispensable in the electronics industry. While other materials, such as graphene and gallium nitride (GaN), show great promise for some applications, the advantage in established infrastructure for silicon fabrication coupled with the cost advantages and robust performance across a wide range of devices secures silicon's place as a core material in electronics for the foreseeable future.