Electronic Material Silicon: What Is It and How Is It Used?

1. Introduction

Silicon is the basic raw material in modern electronics, playing an essential role in everything from integrated circuits to solar cells. This semiconductor material is abundant, cost-effective, and has versatile potential, making it essential in the production process of electronic devices. The electrical properties of silicon, together with its scalability, make it dominant in industries that range from consumer electronics to renewable energy. The paper discusses silicon's properties, production methods, uses, and challenges, focusing on its lasting importance in the science of electronic materials.

2. Basic Properties of Silicon

Silicon is the chemical element denoted by the atomic number 14 and atomic mass 28.0855. It is a hard, brittle crystalline solid featuring a 2.32–2.34 g/cm³ density and a melting point of 1410°C. Silicon is the second most abundant element in the Earth's crust, present in silicates and silica. Its semiconductor properties allow the crystalline structure to increase its conductivity with increased temperature. These properties make silicon indispensable in electronics, where it functions as a key material for integrated circuits, solar cells, and more.

3. Extraction and Production of Silicon

3.1 Preparation of Amorphous and Crystalline Silicon

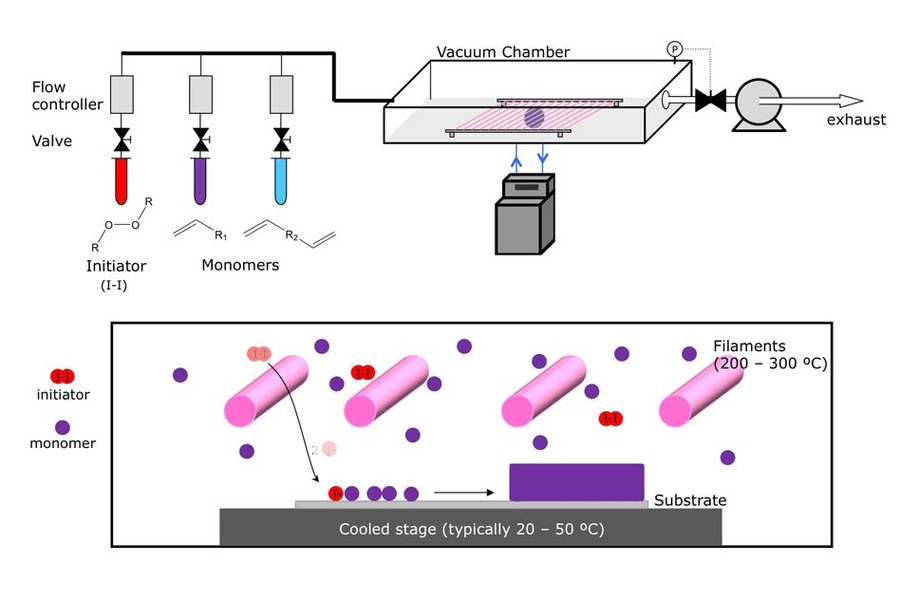

Amorphous silicon is produced by the high-temperature reduction of silica with magnesium and produces a brownish-black powder. Industrial production of crystalline silicon usually involves the reduction of very pure silica (SiO₂ > 99%) with carbon-based reductants such as petroleum coke or charcoal in electric arc furnaces.

3.2 High-purity, monocrystalline, and polycrystalline silicon

High-purity silicon for electronic applications is prepared by the reduction of chemical compounds, such as silicon tetrachloride, with hydrogen: For microelectronic and solar cell applications in particular, single-crystal silicon is required. Single-crystal silicon is currently manufactured primarily by the Czochralski (CZ) pulling method, where a seed crystal is drawn through a bath of molten silicon to produce a single, continuous crystal. Lower-quality polycrystalline silicon is made by heating silicon powder at high temperatures.

4. Silicon in the Electronics Industry

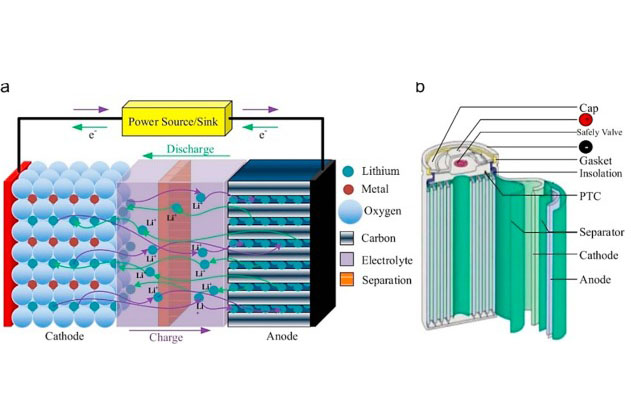

4.1 Integrated Circuits (ICs)

Silicon wafers form the foundation of integrated circuits that are the backbone of devices like smartphones, computers, and other electronic systems. Its ability to efficiently conduct electricity in a controlled manner makes it ideal for ICs, which power virtually every modern electronic device.

4.2 Solar Cells

Monocrystalline silicon solar cells have efficiencies of 20% or higher, which makes them appropriate for high-density applications in residential and commercial solar installations. Polycrystalline silicon solar cells, with somewhat lower efficiencies of 15–18%, are considerably more cost-effective for large-scale solar farms. Silicon thin-film solar cells represent yet another type; they are lightweight and flexible, so they enable new applications in BIPV and portable devices.

4.3 MEMS and Sensors

The stability and semiconductor properties of silicon make it perfect for MEMS and sensors. These devices range from deployable automotive airbags to medical devices, then to consumer electronics like smartphones, where they power functions including accelerometers, gyros, and pressure sensing.

4.4 Power Electronics

The demand for silicon-based power devices like MOSFETs and IGBTs is indispensable in energy conversion for electric vehicles, power supplies, and data centers. Research into silicon-based materials continues to overcome its inadequacies, especially at the extreme environment, in acquiring greater capability.

4.5 Silicon Photonics

Unique properties of silicon allow it to be used in optoelectronic devices, including photodiodes and infrared LEDs. Silicon photonics is now emerging as a promising technology in high-speed data transmission, optical communication, and optical computing, really pushing the boundaries on how modern communication systems process data.

5. Advantages and Limitations of Silicon

5.1 Advantages

• Abundance: Silicon is the second most abundant element on Earth, ensuring a stable and cost-effective supply for global industries.

• High Purity: Advanced purification techniques, such as zone melting, can produce silicon of purities as high as 99.9999%, meeting the very stringent demands of the semiconductor industry.

• Cost-Effectiveness: Its high availability, mature production methods, and stability make silicon an economically viable material, appropriate for large-scale electronic device manufacture.

5.2 Limitations

• High-Temperature Limitations: The conductivity of silicon reduces at high temperatures, restricting its applications in high-temperature conditions for space and military electronics.

• Bandgap Constraints: Silicon has a relatively narrow bandgap of 1.1 eV, thus limiting its performance for high-frequency and high-speed applications. For such uses, materials like gallium arsenide (GaAs) are preferred because they have wider bandgaps and faster switching speeds.

6. Silicon Compared with Alternatives

|

Material |

Band Gap (eV) |

Electron Mobility (cm²/V·s) |

Thermal Conductivity (W/m·K) |

Cost (Relative to Silicon) |

|

Silicon (Si) |

1.1 |

1400 |

149 |

Base Cost |

|

Gallium Arsenide (GaAs) |

1.43 |

8500 |

46 |

Higher Cost |

|

Gallium Nitride (GaN) |

3.4 |

2000 |

130 |

Higher Cost |

|

Graphene |

0 |

~10000 |

~5000 |

High |

|

Silicon Carbide (SiC) |

3.26 |

1000 |

490 |

High |

|

Organic Semiconductors |

1-2 |

~0.1 |

- |

Low |

Data Comparison Explanation:

1. Band Gap: It represents whether the material can conduct or insulate under given conditions. Silicon and GaAs are ideal for low-temperature applications, while GaN and SiC work perfectly in high-power, high-temperature environments. Graphene does not have a band gap, making it unsuitable for traditional switching circuits.

2. Electron Mobility: Higher electron mobility allows for better performance in high-frequency, high-speed operations. Graphene leads in electron mobility, though its lack of a band gap limits its current practical use. GaAs and GaN also offer significantly higher mobility than silicon.

3. Thermal Conductivity: This refers to materials that support high-power electronic heat dissipation. Graphene has the highest thermal conductivity followed by GaN and SiC, which makes them suitable for high-temperature applications.

4. Cost: Silicon is the most cost-effective material, while materials like graphene, GaN, and SiC are currently more expensive due to challenges in their production and manufacturing process. Silicon's mature manufacturing processes make it the most cost-efficient for mass production.

How to Choose:

• Silicon still offers the best cost-effectiveness for traditional electronics in terms of mass production.

• Mainly, it suits high-frequency and high-speed applications such as communication and satellite technology.

• They provide a high performance in high-power and high-temperature conditions, making this material suitable for both power electronics and electric vehicles.

• Graphene holds great potential in ultra-fast and low-power devices but is still held back by production difficulties and high costs.

Organic semiconductors find the widest use in low-cost and flexible electronics, even though performance level issues generally make them unsuitable for high-performance applications.

7. Frequently Asked Questions

Q1: Why is silicon preferred for integrated circuits?

The stable semiconductor properties of silicon, its availability, and reasonable cost make it an ideal material for integrated circuits, which are part of nearly every modern electronic device.

Q2: What is the difference between monocrystalline and polycrystalline silicon?

Monocrystalline silicon contains only one continuous crystal, which provides greater efficiency and performance. Polycrystalline silicon is formed by a multitude of crystals, with lower efficiency, being more cost-effective; it is good for solar panels, but less suitable for high-performance electronics.

Q3: Can silicon be used in high-temperature applications?

Silicon has certain limitations beyond a high temperature because its conductivity decreases with temperature increase. In extreme environments, materials like gallium nitride are often preferred; these have higher thermal and electrical performance at elevated temperatures.

8. Conclusion

It is because of the versatility, abundance, and cost-effectiveness of silicon that it becomes invaluable in the fields of electronics, energy, and sensors. Though silicon faces extreme environments and high-frequency challenges, continuous innovations are opening up possibilities. Its continued relevance to semiconductor manufacturing, renewable energy, and MEMS devices means that silicon will continue to play an important role in the technological future.

Stanford Electronics reinforces these developments with an offer of high-quality silicon material for various applications.

Related Reading: