NMC (Nickel Manganese Cobalt) Cathode Materials Explained

NMC (Nickel Manganese Cobalt) cathode materials have become the pillar for modern-day lithium-ion batteries to move electric vehicles, mobile devices, and energy storage solutions forward. With their high energy density, matched performance, and configurable formulation, NMC materials offer the optimal balance of cost, stability, and capacity.

As the electric vehicle (EV) revolution accelerates, it has become imperative that engineers, researchers, and manufacturers are aware of the fundamentals, manufacturing processes, and market conditions of NMC cathodes.

NMC (Nickel Manganese Cobalt) Basics

--What Are NMC Cathode Materials?

NMC cathodes are layered oxide compounds with a typical composition of LiNixMnyCozO₂, whose proportions of nickel, manganese, and cobalt vary depending on desired performance. NMC cathodes are members of the layered transition metal oxides family, which is related to LiCoO₂ (the cathode chemistry employed in early lithium-ion batteries).

Related reading: List of Anode and Cathode Battery Materials

--Understanding the Role of Nickel, Manganese, and Cobalt in NMC Cathodes

Nickel's very high redox reaction capacity (Ni²⁺ ↔ Ni⁴⁺) is the dominant reason for the high specific capacity of the cathode. Unhappily, high nickel content predisposes the structure to surface degradation and oxygen release with associated loss in performance under high voltage. Manganese is electrochemically inert over the operating voltage but helps mechanically stabilize the layered structure. Cobalt is the most important intermediate participant—it stabilizes the layered phase, facilitates homogenously distributed cations, and enhances electronic conductivity of the cathode.

It is this balance that explains why early NMC chemistries (e.g., NMC111, Ni:Mn:Co = 1:1:1) focused on exact ratios, whereas later high-energy chemistries (e.g., NMC811) pushed nickel to levels over 80% in order to maximize capacity.

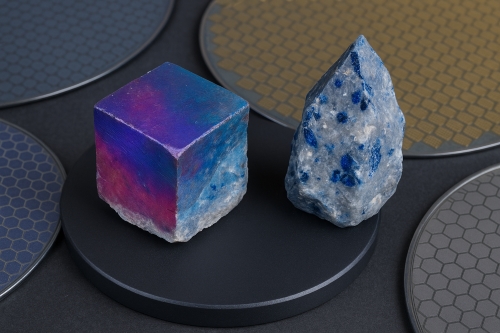

--Crystal Structure and Phase Stability of NMC Materials

NMC cathodes adopt a layered α-NaFeO₂-type crystal structure, space group R-3m. Lithium ions occupy octahedral sites between successive layers of oxygen and transition metal ions. The fast lithium-ion diffusion in the charge and discharge cycles is facilitated by the crystal structure, which is critical for high power output.

However, the layered lattice can degrade when cycled, particularly high voltage or temperature. Cation mixing due to high nickel content occurs, where Ni²⁺ migrates to lithium sites, degrading Li⁺ mobility and capacity retention. Controlled stoichiometry, surface coating, or dopants (e.g., Al, Ti, or Zr) to achieve phase stability have become a prime research and manufacturing focus for extending battery life.

Comparison NMC Materials

--NMC Types and Compositions: NMC111 to NMC811

The NMC cathode history is usually depicted in its numerical fractions.

• NMC111 (Ni:Mn:Co = 1:1:1) offers balanced stability with average energy density.

• NMC532 and NMC622 introduced greater nickel content for greater capacity.

• NMC811 (Ni:Mn:Co = 8:1:1) is the current standard for high-capacity EV batteries, offering up to 200–220 mAh/g of specific capacity compared to approximately 160 mAh/g for NMC111.

The transition to high-nickel, low-cobalt chemistries is driven by economic as well as environmental considerations. Diversification out of cobalt reduces supply risk—given the fact that over 70% of global cobalt supply originates from the Democratic Republic of Congo—while optimizing energy density for longer driving ranges.

--Layered Oxide Cathodes: NMC vs NCA vs LFP

NMC is often compared to NCA (Nickel Cobalt Aluminum) and LFP (Lithium Iron Phosphate) cathodes. NCA has slightly higher energy density, which was the favorite of Tesla in early EVs, but is thermally more sensitive and costly due to greater use of cobalt. LFP, however, possesses better heat stability and greater cycle life but lower energy density (~160 Wh/kg) versus NMC (~200–240 Wh/kg).

As a result, NMC is an intermediate material—of high energy performance, reasonable price, and acceptable safety—yet becoming the chemistry of choice in the majority of EVs and grid storage applications around the world.

How NMC Cathode Powders Are Made: Which Path Leads to Higher NMC Performance?

Making NMC materials involves advanced chemical synthesis and high-temperature sintering. Two dominant modes of production exist for them:

1. Co-precipitation, where metal sulfates or nitrates are reacted with alkaline solutions to form uniform hydroxide precursors, which are then blended with lithium sources and calcined.

2. Solid-state synthesis, where oxide or carbonate powders are mixed mechanically and directly calcined.

Co-precipitation provides higher particle homogeneity, composition homogeneity, and electrochemical performance and is therefore the process of choice in industry for high-quality NMC powders. Particulate morphology—particularly spherical secondary particles composed of nanosized primaries—is directly significant in impacting ionic transport, packing density, and cycling stability.

Future and Emerging Trends

1. NMC vs LFP: Which Cathode Chemistry Drives the Future of EVs?

The LFP-NMC rivalry keeps heating up. LFP batteries are progressively winning market share in low-cost, short-range EVs, particularly in China, while NMC maintains dominance in long-range, high-performance EVs. With ongoing progress in cell-to-pack (CTP) design and structural integration, NMC batteries keep moving towards higher energy density levels above 800 Wh/L at the cell level.

2. The Shift to High-Nickel NMC811 and NMC9½½ Chemistries

Next-generation cathodes like NMC811, NMC9½½, and even cobalt-free ones aim to optimize nickel utilization with structure stabilization through coating and dopants. These materials deliver higher capacity and lower cobalt usage, as in line with sustainability and cost expectations. Surface and interface stability is still a top technical challenge actively being pursued, however.

3. Battery Recycling and Resource Recovery from Spent NMC Cells

As the adoption of EVs accelerated, recycling used NMC cells has become critical. Precious metals—cobalt, nickel, and manganese—are reclaimed through hydrometallurgical and pyrometallurgical techniques to be reutilized in fresh cathodes. Closed-loop recycling of NMC batteries not only offsets raw material shortage but also reduces the carbon footprint associated with battery production by up to 30%.

Global Market Outlook: NMC Cathode Materials Through 2030

The global NMC cathode market is projected to grow from $24 billion in 2024 to nearly $45 billion by 2030, led mainly by the EV market and energy storage systems. High-nickel variants are likely to be at the forefront of this growth, as the study of cobalt-free variants continues to build pace. The switch towards sustainable manufacturing and recycling will also dictate the destiny of NMC materials for the coming decade.

Conclusion

Briefly, NMC cathode materials are the most balanced and diversified answer in the lithium-ion world—finding a middle path between performance and sustainability. As material science evolves, future generations of NMC versions will deliver yet more energy, enhanced safety, and a reduced environmental impact, propelling the next generation of clean energy technologies. For more information, please check Stanford Electronics.