Case Study: Lithium Iron Phosphate Powder for Energy Storage and Batteries

Introduction

Lithium Iron Phosphate Powder (LiFePO4 or LFP) has revolutionized energy storage and battery technologies. Its unique properties have driven advancements in renewable energy systems, electric vehicles, and portable electronics. This article provides an overview of LiFePO4 Powder’s features and applications, offering insights into its transformative role in modern energy solutions.

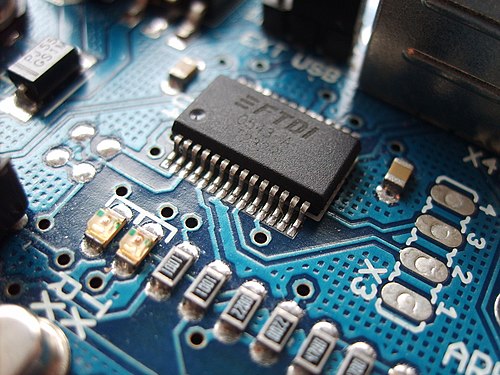

Figure 1. Energy Storage Project

What Is Lithium Iron Phosphate Powder?

Lithium Iron Phosphate (LiFePO4) is an inorganic compound with the chemical formula LiFePO4. It appears as a gray, reddish-gray, brown, or black solid and is insoluble in water. LiFePO4 is a cornerstone material in Lithium Iron Phosphate Batteries, widely used in electric vehicles, solar energy systems, and large-scale grid energy storage solutions.

Figure 2. Lithium Iron Phosphate Powder

Applications of Lithium Iron Phosphate Powder in Energy Storage and Batteries

LiFePO4 Powder’s unique properties make it a preferred material across various energy-related applications:

- Renewable Energy Storage: LiFePO4 Batteries store energy generated from renewable sources like solar and wind, ensuring consistent power supply.

- Electric Vehicles (EVs): The automotive industry relies on LiFePO4 Batteries for their safety, durability, and reliable performance.

- Portable Electronics: LiFePO4’s stability and extended cycle life make it ideal for powering devices like laptops, smartphones, and power banks.

Case Study: Optimizing Lithium Iron Phosphate Powder for Battery Applications

The Challenge

A customer sought to optimize Lithium Iron Phosphate Powder for lithium electronic batteries. The objective was to enhance efficiency, energy density, and overall battery performance.

The Solution

Stanford Advanced Materials (SAM) recommended strategic factors for optimizing battery design:

- Particle Size: Finer LiFePO4 Powder (1–10 microns) enhances reaction speed and charge/discharge efficiency.

- Crystal Type: Consideration of crystal types such as orthogonal (OLP) and monoclinic (MLP) ensures suitability for specific performance needs and manufacturing processes.

- Ultrafine Powder: Meter-grade ultrafine powders with higher surface areas increase reactive sites, improving energy density and cycle life.

- Composition Uniformity: High-purity LiFePO4 Powder with minimal impurities enhances overall battery reliability and performance.

The Results

By optimizing factors like particle size, crystal type, ultrafine grade, and purity, the customer achieved batteries with superior efficiency, energy density, and longer cycle life.

Conclusion

Lithium Iron Phosphate Powder (LiFePO4) is a key material driving innovation in energy storage and batteries. Its safety, stability, and long cycle life make it indispensable for renewable energy systems, EVs, and portable devices. As energy demands grow, LiFePO4 continues to play a pivotal role in powering a sustainable future.

Stanford Electronic supplies high-quality LiFePO4 Powder in various sizes and purities, with customization options to meet specific requirements. Contact us for inquiries and solutions tailored to your needs.