Which Sputtering Targets Are Used in the Semiconductor Industry?

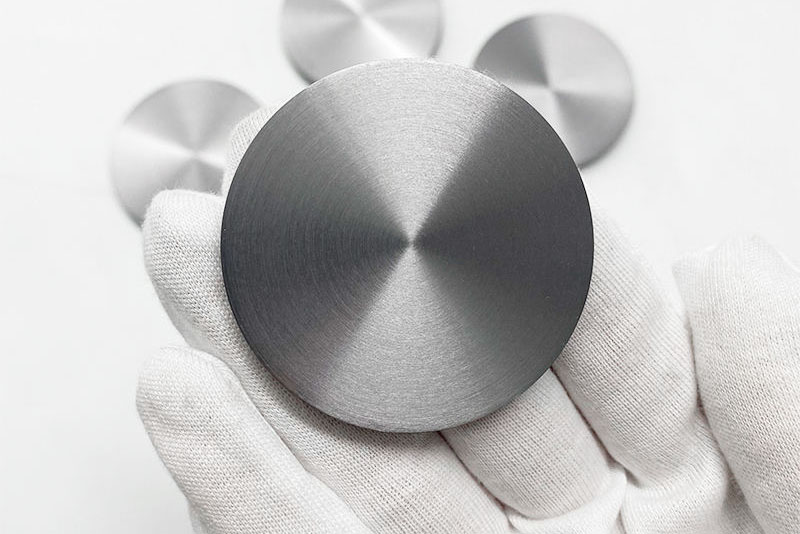

Sputtering is an essential process in semiconductor manufacturing, allowing the deposition of thin films onto substrates for various applications. These thin films are critical for the performance of semiconductor devices like microchips, sensors, solar cells, and memory devices. Here offers the types of sputtering targets used in the semiconductor industry with their specific applications.

![]()

1. Metal Sputtering Targets

Metal sputtering targets have widespread applications in semiconductor fabrication processes as metals possess excellent electrical conductive properties and adhesive characteristics. The common metals employed in semiconductor industries include aluminum, copper, gold, and titanium.

- Aluminum finds a lot of applications as a sputtering target in semiconductor devices because of its superior electrical conductivity, economics, and ability to produce a high-quality film. Aluminum thin films find applications in metallization, mainly in interconnect layers in microchips. Aluminum is used in wire bonding in semiconductor devices and in memory storage.

- Copper has far greater electrical conductivity than that of aluminum. In this way, copper is considered to be ideal for use in future semiconductor technology and high-performance interconnect technology. Due to low resistivity and further scaling down in size for semiconductor devices, use in back-end-of-line interconnect technology on future semiconductors is becoming more and more imperative.

- Gold sputtering targets are to be made use of higher electrical conductivity along with stability. Gold as a material is widely considered useful for the production of high-quality films of electrodes. It is often made use of in wire bonding of semiconductor devices due to its desirable properties of high frequency and reliability.

- Titanium: It is widely used as a target for semiconductor processing by sputtering. The key advantages are its high boiling point and its capability to develop high adhesive bond strength against other materials. The titanium thin film has its main application as an adhesive barrier to prevent copper from diffusing to other materials during copper metallization. Its second application as an adhesion material aids in enhancing the bond between materials.

2. Alloy Sputtering Targets

Alloy Sputtering Targets are a combination of two or more elements to provide better properties for a certain semiconductor application.

- Tungsten-copper alloys are required for their good thermal conductivity properties as well as high temperature stability. Tungsten-copper alloys can be used for the fabrication of microelectromechanical systems as well as for the fabrication of power devices that require high heat resistance.

- Tantalum and tantalum nitride alloys are commonly applied as barrier materials for copper interconnects. Tantalum has superior corrosion resistance and high-temperature stability, and tantalum nitride (TaN) is very effective at preventing copper from diffusing into other layers, which could impair device performance.

- Titanium-tungsten alloys: Another type of alloy sputtering target used in semiconductor processing is that of titanium-tungsten. This material takes advantage of the high melting point strength of tungsten, along with the adhesive qualities of titanium.

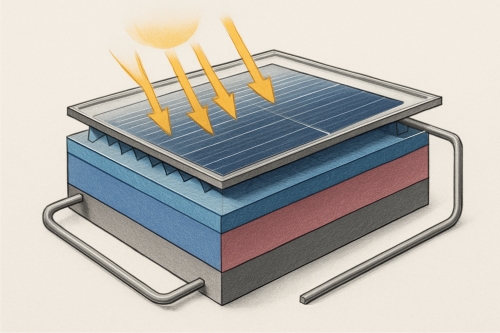

3. Ceramic Sputtering Targets

The ceramic type of sputtering target material is normally utilized in the situation necessitating insulating material properties, hardness, or specific chemical resistivity. Some of the ceramic materials used for making targets for sputtering include silicon dioxide, silicon nitride, and hafnium dioxide.

- Silicon Dioxide, or SiO₂, is a widely utilized insulator with a vast range of uses in semiconductor device manufacturing. The substance is deposited as a thin film in order to obtain gate oxides in field-effect transistors and as a separating metallic layer in semiconductor device manufacturing, specifically in integrated circuits. Silicon dioxide thin films can also be applied as layers for protecting the semiconductor components from damage by their environments.

- Another important ceramic sputtering target is silicon nitride, Si₃N₄, which is extremely hard and chemically resistant. Silicon nitride films are used as passivation layers in semiconductor devices to provide protection against moisture, contaminants, and mechanical stresses. Besides this, silicon nitride is employed for structural layers in MEMS devices, where its hardness and mechanical properties are highly important for the integrity of these devices.

- Other ceramics include aluminum oxide (Al₂O₃) and titanium oxide (TiO₂), used in specific applications where additional properties such as high dielectric constant, resistance to wear, or UV transparency are required. These ceramic films find their application mainly in advanced capacitor technologies or as an insulating layer in different electronic devices.

Comparison of Sputtering Targets in Semiconductor Manufacturing

|

Material |

Properties |

Applications |

|

Aluminum (Al) |

High conductivity, low cost, good adhesion |

Interconnects, wire bonds, memory devices |

|

Copper (Cu) |

Excellent conductivity, low resistivity |

High-performance interconnects, BEOL interconnects |

|

Titanium (Ti) |

High melting point, good adhesion |

Barrier layers, adhesion layers |

|

Tungsten (W) |

High thermal stability, high density |

Contact electrodes, power devices |

|

Silicon Dioxide (SiO₂) |

Insulator, good dielectric properties |

Gate oxides, capacitors, isolation layers |

|

Cobalt (Co) |

Magnetic properties, good conductivity |

Magnetic layers in HDDs, MRAMs |

|

Gold (Au) |

High conductivity, corrosion resistance |

Electrodes, optical coatings, wire bonding |

For more information, please visit Stanford Electronics.

Conclusion

Sputtering targets are indispensable in semiconductor manufacturing. Metal sputtering targets are critical for interconnects and electrode films, while alloy targets serve specialized functions like diffusion barriers in copper interconnects. Ceramic sputtering targets are essential for creating insulating layers, dielectric films, and advanced materials like high-k dielectrics.