Common Examples of Magnetic Materials Used in Electronics

Magnetic materials are the foundation of modern electronics. Based on structure and composition, magnetic materials can be categorized according to how easily they retain or release magnetization—whether as permanent (hard) or temporary (soft) magnets.

In electronics, magnetic materials are used in motors, sensors, inductors, transformers, magnetic storage devices, and microwave devices. To better understand how these materials are used in electronic circuits, let's explain the common types and examples in more detail.

Hard Magnetic Materials (Permanent Magnets)

Hard magnetic materials, also called permanent magnets, retain their magnetic properties over time and resist demagnetization even in strong external fields. These materials are defined by their high coercivity, large hysteresis loops, and a high maximum magnetic energy product, making them suitable for devices requiring consistent magnetic performance.

One well-known example is Alnico alloys, composed primarily of aluminum, nickel, and cobalt. These materials are prized for their high Curie temperature (up to 860°C) and excellent thermal stability, which allow them to operate reliably in high-temperature environments. Their strong coercivity ensures resistance to demagnetization, while their corrosion resistance makes them suitable for rugged conditions. Alnico magnets are widely used in electric guitars, sensors, and industrial equipment.

Another important permanent magnet is the titanium-cobalt alloy, known for its high magnetic induction—reaching up to 1.25 Tesla—and low energy loss during magnetic field reversal. These properties make titanium-cobalt alloys especially effective in electric motors and generators operating under varying loads or high temperatures. Thanks to the precision alloying of cobalt, vanadium, and other elements, these materials combine mechanical strength with magnetic performance, ensuring reliability in demanding conditions.

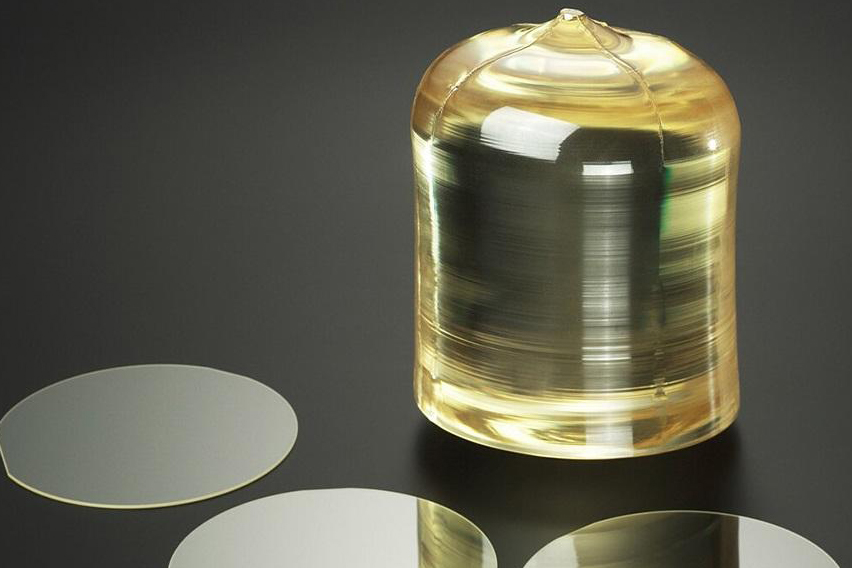

Among the most advanced permanent magnets are rare earth cobalt magnets, including the RCo₅ and R₂Co₁₇ families (R represents rare earth elements like samarium or praseodymium). These magnets exhibit extremely high magnetic anisotropy and energy density. With preparation methods such as powder metallurgy and precision casting, they are used in specialized applications including microwave devices, magnetrons, traveling wave tubes, and microelectronic instruments. Their resilience and high performance make them indispensable in both aerospace and high-frequency electronics.

Soft Magnetic Materials

Unlike hard magnetic materials, soft magnetic materials can be magnetized and demagnetized easily. They exhibit low coercivity (typically under 1000 A/m) and high magnetic permeability, which means they require very little energy to reach their maximum magnetization. This makes them ideal for alternating current (AC) applications, where magnetic fields are constantly changing.

Silicon steel, a type of soft magnet, is extensively used in transformers, motors, and inductors. It combines high saturation magnetic induction with low hysteresis and eddy current losses. Its high electrical resistivity reduces energy dissipation, while its ease of fabrication into thin sheets enables efficient manufacturing of transformer cores and motor laminations. Variants include cold-rolled non-oriented and oriented electrical steel, widely used in power electronics operating at frequencies up to 400 Hz.

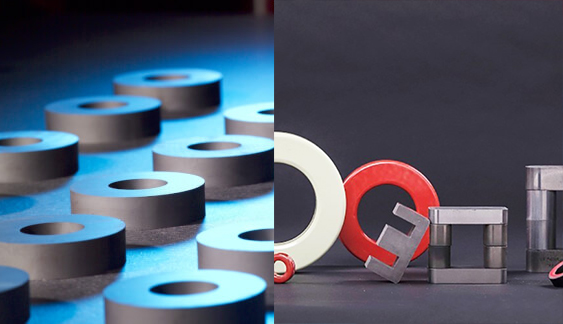

Another major class is soft magnetic ferrites, which are ceramic compounds made of iron oxide mixed with other metal oxides. Although they have relatively low saturation flux density and Curie temperatures, their key advantages lie in their high electrical resistivity and low loss at medium to high frequencies. These properties make ferrites ideal for RF transformers, inductors, EMI suppression, and switch-mode power supplies. Their low cost and frequency performance have led to widespread adoption in consumer electronics, telecommunications, and automotive electronics.

Soft magnetic materials serve numerous roles in electronic components. In motors and generators, they form the core of rotors and stators, improving efficiency and energy density. In transformers and inductors, their low hysteresis loss ensures effective power transfer with minimal heat generation. Additionally, they play vital roles in electromagnetic shielding, magnetic sensors, and induction heating systems, contributing to reduced interference and improved operational stability.

Magnetic Alloys

Magnetic alloys, produced by the blending of iron with elements like cobalt, nickel, or rare earth metals, have designed magnetic properties suitable for a range of applications. Magnetic alloys tend to be of soft and hard magnetic types based on their magnetic properties.

Soften magnetic alloys such as iron-nickel and silicon steel alloys have high permeability and low coercivity and are thus best in the use in power transformers, chokes, and magnetic shields. Such materials find application in power electronics, household appliances, and electric vehicles where minimization of energy loss is paramount.

Hard magnetic alloys such as neodymium-iron-boron (NdFeB), Alnico, and cobalt magnets have high magnetic energy product and retentivity. NdFeB magnets are particularly known for their high strength and are ideal for small, high-power applications such as electric vehicle drives, wind generators, and advanced magnetic resonance imaging (MRI) systems. Alnico alloys remain favored in high-temperature applications, and cobalt magnets are used in precision equipment requiring stability along with magnetic power.

Each alloy is carefully formulated to reach a balance of magnetic strength, thermal stability, corrosion resistance, and mechanical durability in order to enable the engineers to select the optimal material for specific functional requirements in electromechanical devices and electronic uses.

Conclusion

Magnetic materials are the backbone of modern electronics. Alnico, titanium-cobalt, and rare earth magnets deliver consistent performance in demanding environments, while silicon steel and ferrites provide energy-efficient solutions for dynamic systems. Magnetic alloys, meanwhile, bridge the performance needs across soft and hard categories, enabling technological progress in everything from household appliances to space-grade devices. For more information, please visit Stanford Electronics.