What Is Indium Tin Oxide and Why Is It Everywhere?

Despite being virtually transparent, ITO is one of the most widely used materials in modern electronics. It’s in your smartphone, your laptop, your television, and even the solar panels on your roof. So what exactly is it, and why has it become so essential?

A Transparent Conductor

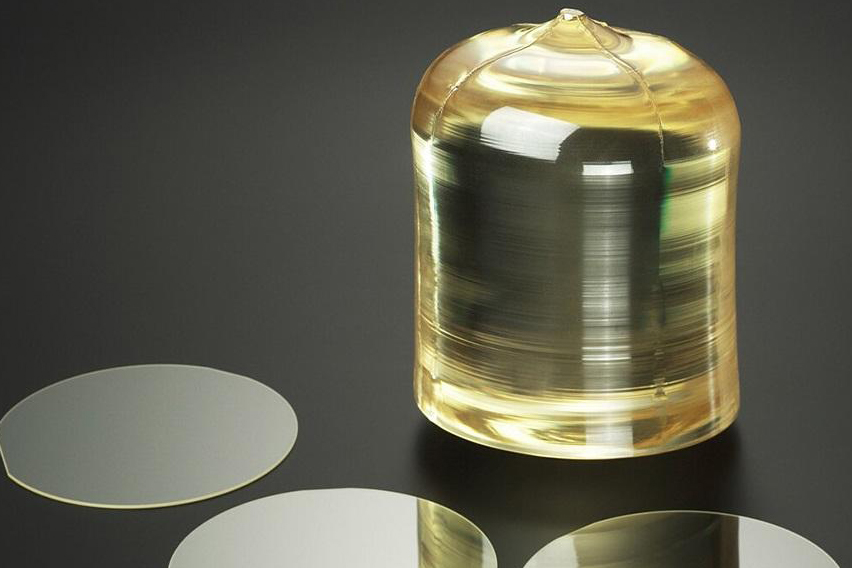

Indium tin oxide is a ceramic material composed of about 90% indium oxide (In₂O₃) and 10% tin oxide (SnO₂) by weight. The magic of ITO lies in its rare combination of properties—it is both electrically conductive and optically transparent.

- Transparency: ITO transmits up to 85% or more of visible light, making it ideal for screens and displays.

- Conductivity: ITO conducts electricity efficiently across very thin layers, which allows it to function as an electrode.

That’s an unusual and powerful combination. Most conductors block light (like metals), and most transparent materials don’t conduct electricity (like glass). ITO does both, and that’s why it's everywhere.

Fig. 1 Different ITO and Touchscreens [1]

Where You’ll Find ITO

You’ve likely interacted with ITO today without even knowing it. Some of its most common applications include:

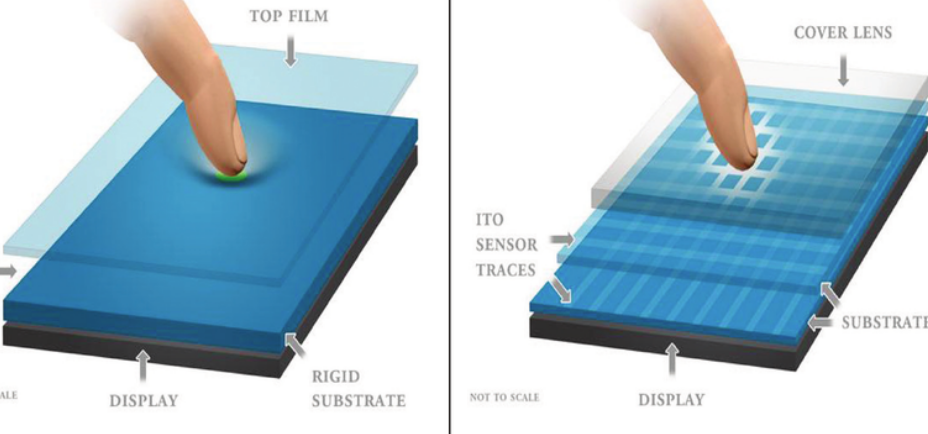

- Touchscreens: ITO forms the transparent electrode layer that senses your touch on smartphones, tablets, and kiosks.

- Flat-panel displays: It’s used in LCDs, OLEDs, and LED displays to control pixels and maintain image brightness.

- Solar cells: In thin-film photovoltaic cells, ITO allows sunlight in while collecting the electrical charge.

- Smart glass: ITO-coated glass can change tint in response to electricity, enabling energy-efficient windows.

- Optoelectronics: Devices like LEDs, laser diodes, and photodetectors often use ITO as a contact layer.

A single smartphone screen might contain only about 20 to 30 milligrams of indium, but multiply that across billions of devices, and demand quickly adds up.

How ITO Is Made and Applied

ITO is typically applied to surfaces using sputter deposition, a vacuum-based process where high-energy particles knock atoms from a solid ITO target onto a substrate—often glass or plastic. The result is a nanometer-thin coating, just 100 to 300 nm thick.

Once applied, the film may be annealed (heated) to improve its conductivity and adhesion. Engineers can fine-tune its performance by adjusting thickness, temperature, or composition, depending on the application.

![]()

Fig. 2 ITO glass substrate image with patterned ITO and pixel-defined layer [2]

Why ITO Still Dominates

Even though alternatives are being explored, ITO remains the top choice for transparent conductors. Here’s why:

- Excellent performance: ITO achieves a rare balance of high transparency and low resistance.

- Proven technology: Manufacturers have decades of experience working with it.

- Reliable sourcing: Despite concerns about indium availability, ITO production is well-established.

In short, it works—and works well.

The Problem with Indium

There’s one big catch: indium is scarce. It’s not mined directly but recovered as a byproduct of zinc refining. That limits how much we can produce. As of 2024, more than 60% of global refined indium comes from China, raising concerns about supply and geopolitical risk.

Moreover, ITO is brittle, which makes it difficult to use in flexible or bendable electronics—an area of rapid growth.

The Search for Alternatives

Researchers are actively exploring ITO replacements, especially for flexible devices. Some candidates include:

- Graphene: Extremely thin and conductive, but hard to scale up.

- Silver nanowires: Very flexible and transparent, but more expensive.

- Conductive polymers: Promising but still less stable than ITO in the long run.

- Aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO): Less expensive but usually not as conductive or transparent.

For now, none of these materials have fully matched the performance and industrial reliability of ITO—especially in large-scale production.

|

Material |

Transparency |

Conductivity |

Flexibility |

Scalability |

Cost |

|

ITO |

★★★★★ |

★★★★★ |

★☆☆☆☆ |

★★★★★ |

★★☆☆☆ |

|

Graphene |

★★★★★ |

★★★★★ |

★★★★★ |

★★☆☆☆ |

★☆☆☆☆ |

|

Silver Nanowires (AgNWs) |

★★★★★ |

★★★★★ |

★★★★★ |

★★★☆☆ |

★★☆☆☆ |

|

Conductive Polymers |

★★★★☆ |

★★☆☆☆ |

★★★★★ |

★★★★★ |

★★★☆☆ |

|

AZO |

★★★★☆ |

★★★☆☆ |

★★★★☆ |

★★★★★ |

★★★★★ |

|

FTO |

★★★★☆ |

★★★☆☆ |

★☆☆☆☆ |

★★★★★ |

★★★★★ |

Final Thoughts

Indium tin oxide may be invisible to the eye, but it’s foundational to modern electronics. It brings clarity and interactivity to our devices while quietly enabling energy generation and smart infrastructure.

As demand grows for more efficient, flexible, and sustainable tech, the question isn’t whether we need transparent conductors—it’s whether ITO can keep up, or if something better will finally take its place. Either way, the future of electronics remains clear—and ITO is still right at the surface. For more information, please visit Stanford Electronics.

Reference:

[1] Choi, Yu & Shin, Han & Son, Jongchan & Park, Chunhee & Park, Keun-Woo & Lee, Jin-Kyun & Jung, Byung. (2020). Two-Color Pixel Patterning for High-Resolution Organic Light-Emitting Displays Using Photolithography. Micromachines. 11. 650. 10.3390/mi11070650.

[2] Souza, C & Sant'Ana, Pericles & Bortoleto, J. & Durrant, Steven. (2022). ISSN (online) 2583-455X Measurement of the Surface Electrical Resistance of SnO 2 :F Thin Films.