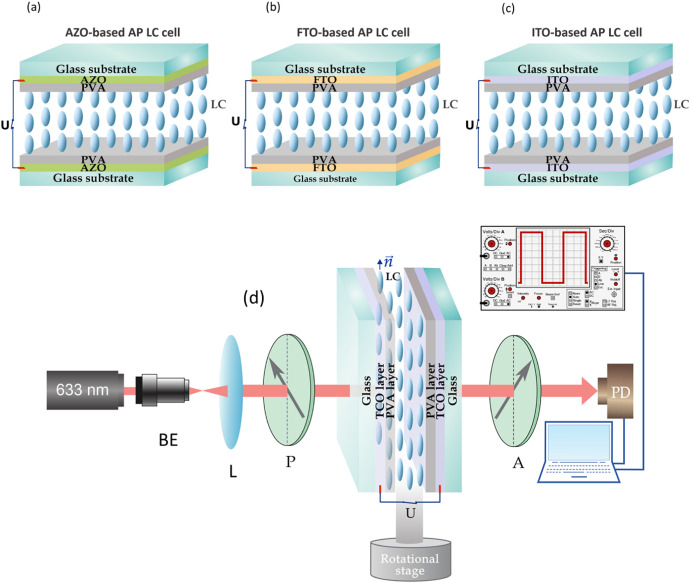

Comparing Transparent Conducting Oxides: ITO, AZO, and FTO

Transparent Conducting Oxides (TCOs) are critical materials in modern optoelectronic and energy devices, combining high electrical conductivity with significant optical transparency. Among the most widely adopted TCOs are Indium Tin Oxide (ITO), Aluminum-doped Zinc Oxide (AZO), and Fluorine-doped Tin Oxide (FTO).

[1]

1. Indium Tin Oxide (ITO)

Indium Tin Oxide remains the most commercially advanced TCO. It is an alloy of indium oxide and tin oxide, typically in 90:10 ratios, and is highly prized for its excellent electrical conductivity and visible transparency—sometimes up to 80–90%. These attributes render ITO a prized material in touchscreens, OLEDs, and solar cells. Its thin-film deposition techniques are mature and highly optimized, which results in its ongoing market leadership.

However, indium dependence of ITO poses serious issues. Indium is scarce and costly, raising long-term sustainability and market instability issues. ITO is mechanically brittle, tends to crack on stress, which hinders its feasibility in wearable or flexible electronics. Environmental challenges with indium extraction and waste disposal make it difficult to support its future usability.

2. Aluminum-doped Zinc Oxide (AZO)

Alternatively, Aluminum-doped Zinc Oxide is a cheaper and more environmentally friendly option. AZO is formed by introducing a small percentage of aluminum into zinc oxide, typically between 1–5%. Like ITO, AZO possesses high visibility transparency and can possibly match the optical performance. Its electrical conductivity, while typically weaker than that of ITO, is controllable through doping levels and process conditions.

AZO's strongest point is mechanical flexibility. Compared to ITO that is brittle, AZO is a good choice for use in flexible devices and therefore for emerging applications like bendable displays and wearable solar cells. Furthermore, the use of abundant and nontoxic elements like zinc and aluminum makes AZO cheaper and more environmentally friendly. All that notwithstanding, AZO performance can be sensitive to doping uniformity and material defects, such as oxygen vacancies, which may affect consistency at large-scale production.

3. Fluorine-doped Tin Oxide (FTO)

Fluorine-doped Tin Oxide stands out for its resilience and environmental stability. Composed of tin oxide doped with fluorine (typically 1–10%), FTO provides reasonable electrical conductivity and moderate optical transparency, usually around 70–80%. While it does not match the transparency or conductivity of ITO, FTO excels in mechanical strength and corrosion resistance.

These properties make FTO especially suitable for outdoor and rugged applications, including solar panels and environmental sensors. It withstands harsh conditions far better than ITO or AZO and is more mechanically durable overall. Additionally, the use of more accessible elements like tin and fluorine makes it less susceptible to supply constraints. However, FTO’s lower transparency can be a limitation in display technologies, and its high-temperature deposition process restricts its use with flexible or temperature-sensitive substrates.

How to Select Transparent Conducting Oxides

In comparing these three materials, the choice ultimately lies in a weighing of performance, cost, ecological sustainability, and mechanical demands. ITO remains the benchmark high-performance material, but its restrictive limitations in terms of flexibility and sustainability are causing researchers to pursue alternatives. AZO offers an encouraging middle point—transparent, flexible, earth-abundant—yet still falling short of ITO on conductivity. FTO, not as optically pure, is stable and strong under extreme environments, and as such is the material of preference for hard-duty, outdoor environments.

In the future, the way ahead for TCO development is continued optimization of such materials and finding entirely new classes of conductors. New doping methods aim to improve conductivity without degrading transparency. Moreover, novel materials such as graphene and carbon nanotubes are also under consideration since they can potentially combine high conductivity, flexibility, and optical transparency in one material system.

Whether through improved versions of ITO, AZO, and FTO, or through entirely new material platforms, transparent conductors will continue to play a vital role in the evolution of next-generation semiconductors.

Reference:

[1] Vera Marinova, Stefan Petrov, Dimitrina Petrova, Blagovest Napoleonov, Nguyen Hong Minh Chau, Yu Pin Lan, Velichka Strijkova, Ken Yuh Hsu, Dimitre Dimitrov, Shiuan Huei Lin, Effect of transparent conductive layers on the functionality of liquid crystal devices: Comparison of AZO, FTO and ITO, Optical Materials: X, Volume 22, 2024, https://www.sciencedirect.com/science/article/pii/S2590147824000421