What You Should Know About Boron Nitride Nanotubes

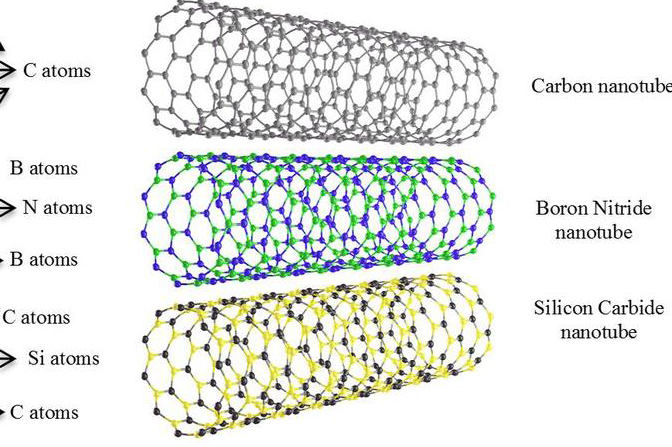

In the world of nanomaterials, boron nitride nanotubes (BNNTs) are perhaps the less glamorous but equally powerful cousins of carbon nanotubes (CNTs). While CNTs have been the poster child for nanotechnology applications for some time now, BNNTs have their own set of impressive properties that render them highly valuable in high-performance materials, electronics, aerospace, and even biomedical applications.

What Are Boron Nitride Nanotubes?

Boron nitride nanotubes are nano-cylindrical structures composed of boron and nitrogen atoms arranged in a hexagonal lattice structure, structurally analogous to carbon nanotubes. BNNTs are structurally akin to hexagonal boron nitride (h-BN), also referred to as "white graphene." Like CNTs, BNNTs can either be single-walled (SWBNNTs) or multi-walled (MWBNNTs) nanotubes, having diameters typically between 1–5 nanometers and lengths reaching up to several micrometers.

First predicted in 1994 and experimentally synthesized in 1995, BNNTs have since attracted a lot of interest in their mechanical strength, thermal stability, and insulation properties, rendering them an exciting material for future uses.

New Properties of BNNTs

BNNTs possess a multitude of properties that distinguish them from other nanotubes, most particularly carbon nanotubes:

1. Excellent Thermal Stability

BNNTs can withstand temperatures over 900°C in air, while carbon nanotubes begin to oxidize at approximately 400–600°C. This property of BNNTs being resistant to heat and oxidation has made them highly desirable for applications in extreme environments, such as aerospace and power systems.

2. Electrical Insulation

Unlike CNTs, which are metallic or semiconducting depending on their chirality, BNNTs are electrical insulators with a wide and nearly constant bandgap of about 5.5–6 eV—irrespective of their diameter or chirality. This would render them ideal for insulating components in nanoelectronics.

3. Mechanical Strength and Flexibility

BNNTs are mechanically strong, having tensile strength the same or even superior to that of CNTs. They possess a Young's modulus of about 1.2 TPa and are flexible and strong—characteristics that make them ideal for composite reinforcement for structural uses.

4. High Thermal Conductivity

They also possess high thermal conductivity, similar to CNTs, making them useful for use as thermal interface materials in electronic devices or as fillers in polymer composites in applications requiring efficient heat dissipation.

5. Biocompatibility

Initial research indicates that BNNTs are non-toxic and biocompatible, with potential biomedical applications in drug delivery, tissue engineering, and biosensors.

Synthesis Methods

BNNTs are challenging to synthesize in large quantities with consistent quality, but several synthesis methods have evolved over time:

• Arc Discharge and Laser Ablation: Used for high-purity, low-quantity laboratory-scale synthesis.

• Chemical Vapor Deposition (CVD): More scalable but potentially needs post-treatment to remove impurities.

• Ball Milling and Annealing: Inexpensive but less controllable in terms of quality and tube structure.

• Plasma-Based Techniques: High yielding and promise large-scale industrial production.

Despite these developments, commercial-scale production is limited, and ongoing research aims to improve yield, purity, and economy.

Applications of Boron Nitride Nanotubes

Thanks to their strength characteristics, BNNTs are finding uses in a wide variety of high-performance applications:

1. Aerospace and Defense

Light weight and thermal stability make BNNTs suitable for spacecraft shielding, structural composites, and thermal management systems. NASA has researched BNNTs for applications ranging from radiation shielding to lightweight spacecraft components.

2. Electronics and Semiconductors

Although BNNTs are insulators, they're useful as gate insulators, dielectric layers, or thermal fillers in semiconductor devices because of their stability and thermal resistance. They're applicable in advanced packaging materials for microelectronics.

3. Energy Storage and Conversion

BNNTs can introduce enhanced thermal stability and mechanical integrity into batteries and fuel cells. They're also being explored to enhance ionic conductivity in solid-state electrolytes and separators.

4. Biomedical Engineering

With their chemically inert and non-toxic nature, BNNTs have been explored for drug delivery, biosensors, and even cancer therapy. Functionalized BNNTs can carry therapeutic agents and release them in a controlled manner, offering a platform for targeted therapy.

5. Composite Materials

Dispersed in polymers or ceramics, BNNTs greatly improve mechanical strength, thermal conductivity, and oxidation resistance. Applications vary from protective coatings and flame retardants to high-performance sports equipment.

BNNTs vs. Carbon Nanotubes (CNTs)

While both BNNTs and CNTs share nanoscale geometry and exceptional strength, their differing properties determine their applications:

|

Property |

CNTs |

BNNTs |

|

Electrical |

Conductive (varies) |

Insulating (wide bandgap) |

|

Thermal Stability |

~500°C in air |

>900°C in air |

|

Chemical Stability |

Prone to oxidation |

Chemically inert |

|

Biocompatibility |

Variable |

High |

|

Cost/Availability |

More commercial sources |

Limited production |

Where insulation, heat resistance, or chemical inertness is paramount, BNNTs are generally superior to CNTs. Cost and availability are their greatest limitations.

Conclusion

Boron nitride nanotubes are a promising and powerful nanomaterial with an exceptional combination of strength, stability, and versatility. While still more expensive and less available than carbon nanotubes, BNNTs offer solutions where traditional materials fail—particularly in aggressive environments, sensitive electronics, and biomedical uses.

As understanding grows and production spreads, BNNTs will become a cornerstone of high-performance materials in the 21st century. For more advanced materials, please check Stanford Electronics.

Reference:

[1] Mercan, Kadir & Civalek, Ömer. (2017). Comparison of small scale effect theories for buckling analysis of nanobeams. International Journal Of Engineering & Applied Sciences. 9. 87-97. 10.24107/ijeas.340958.