Why Indium Matters in the Semiconductor World

When we talk about semiconductors, elements like silicon, gallium, or even rare earths usually get all the attention. But quietly working behind the scenes is indium, a rare metal that plays a critical role in making electronics faster, smaller, and more efficient.

Even though indium makes up only a tiny fraction of the Earth’s crust, it is essential to the semiconductor industry. From the displays on our smartphones to the lasers that power high-speed data communication, indium is found in technologies that define modern life.

What Makes Indium Special

Indium is element number 49 on the periodic table. It is soft, silvery-white, and highly ductile. It melts at just 156.6 degrees Celsius and conducts electricity well. These properties make it ideal for sensitive electronic components that must perform reliably under heat, stress, and rapid cycles.

Unlike other metals, indium is not mined directly. It is typically recovered as a byproduct during the refining of zinc, and to a lesser extent from copper and lead ores. This means indium’s supply is tied to the production of other metals. In recent years, global production has stayed close to 870 metric tons, with China, South Korea, and Canada leading the way.

Indium in Compound Semiconductors

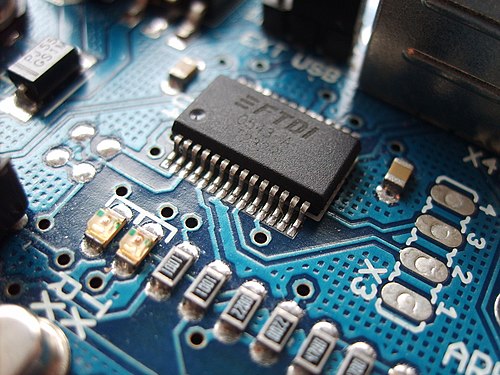

Indium is widely used to create advanced compound semiconductors that outperform traditional silicon in specific applications. Two of the most important are indium phosphide and indium gallium arsenide.

Indium phosphide is a high-speed, direct bandgap semiconductor with excellent electron mobility. This makes it essential for high-frequency devices. It enables technologies such as fiber-optic communication systems, 5G components, and laser diodes. These systems often operate at speeds of 100 to 400 gigabits per second per channel.

Indium gallium arsenide is especially good at detecting infrared light. It is used in night vision equipment, laser range finders, and semiconductor inspection tools. It covers the infrared spectrum between 900 and 1700 nanometers, a range silicon sensors cannot handle.

Indium in Transparent Conductive Films

One of the most visible uses of indium is in indium tin oxide, often abbreviated as ITO. ITO is both transparent and conductive, which makes it perfect for use in touchscreens, display panels, and solar cells.

ITO layers are extremely thin, often between 100 and 300 nanometers. They allow over 85 percent of visible light to pass through while also carrying electrical signals. Without ITO, touchscreens and high-resolution displays would not be possible. The average smartphone contains around 20 to 30 milligrams of indium, mostly in the screen.

Indium in Soldering Applications

Indium is also used in low-temperature solders, which are critical for assembling delicate semiconductor devices. These solders are especially useful when bonding materials with different rates of thermal expansion or when working with heat-sensitive components.

Indium-based solders are flexible and can absorb stress caused by thermal cycling. This improves the reliability of devices used in aerospace, defense, and medical systems. These solders are often found in laser modules, RF chips, and thermal management components.

A Metal with Supply Challenges

Indium is considered a critical raw material by many governments. Its supply is limited, and more than half of the world’s refined indium comes from China. Since it is a byproduct, increasing production is not straightforward.

To reduce risks, many manufacturers are investing in recycling programs. ITO targets from display manufacturing and used panels can be processed to recover indium. Researchers are also exploring alternative materials like silver nanowires or conductive polymers, though none have matched the overall performance of indium.

Looking Ahead

Indium may not be widely known, but it plays a foundational role in modern electronics. It supports high-speed data networks, powers advanced imaging systems, and enables the brilliant displays we use every day.

As demand for faster and more efficient devices continues to rise, so will the importance of indium. For now, it remains one of the key elements helping to shape the future of the semiconductor industry. For more information, please visit Stanford Electronics.